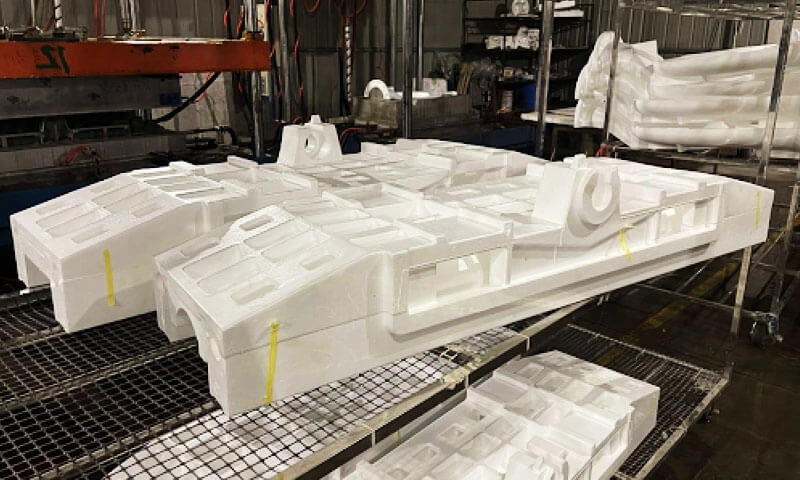

Lost foam casting offers a smart and effective way to create detailed metal parts with great accuracy. This method starts by making precise patterns from expanded polystyrene (EPS) foam. These patterns get coated and placed in sand before hot molten metal is poured in. The foam burns away fully, leaving a sharp metal casting behind. Many industries use it, including automotive, agriculture, marine, military, and heavy equipment. It works especially well for complicated shapes and large production runs. The next parts look at six main advantages that make this approach popular in today’s foundries.

1. Exceptional Dimensional Accuracy

A major strength of lost foam casting comes from its outstanding ability to reach high dimensional accuracy. The process relies on EPS foam patterns that fill the mold completely. This captures every small detail, even narrow internal paths and tricky shapes.

Older casting ways often need to join several pattern parts together. That can cause alignment mistakes and uneven results. Lost foam casting, however, lets the whole pattern form as one solid piece. This near-net-shape feature helps copy design plans exactly. It cuts down on errors and lowers the number of rejected parts due to size issues.

Modern EPS machines play a key role. They produce foam patterns with steady density and strong structure. The outcome is castings that hold tight tolerances all over, even in hard internal areas. This precision fits applications that need strong reliability, such as engine parts and hydraulic systems.

2. Reduced Machining and Processing Steps

Lost foam casting greatly simplifies production by cutting out many extra steps. Traditional methods usually require a lot of machining to remove extra material, smooth surfaces, and join separate cast pieces.

With lost foam, parts come out very close to final size. They need little finishing work. The process creates less flash and uses less extra metal, since the foam pattern shapes the cavity exactly. This saves time, lowers labor needs, shortens production time, and uses less energy.

Also, the smooth surface finish from the mold often skips extra treatment steps. Manufacturers gain from less tool wear and less waste. These factors lead to lower costs and a greener operation. The shorter workflow speeds up getting complex parts to market without losing quality.

3. Seamless Integration of Complex Assemblies

Complicated designs no longer require several parts welded or joined after casting. Lost foam casting shines at combining detailed assemblies into one single casting. This improves overall strength and removes weak spots.

Features like internal passages, thin walls, and undercuts appear often in parts such as engine blocks, cylinder heads, exhaust manifolds, and cooling housings. They form easily in this process. It avoids separate cores or joining work, which might add weakness or poor alignment.

Design freedom adds to this advantage. Changes to patterns happen fast without new tooling, unlike standard sand casting. This flexibility supports ongoing improvements during a product’s life. It makes lost foam perfect for changing needs in tough industries.

4. Compatibility with Multiple Molten Metals

Material choice flexibility makes lost foam casting stand out. The process handles various molten metals, as long as they get hot enough to burn away the EPS foam pattern cleanly.

Common metals include gray and ductile iron, aluminum, brass, and stainless steel. This wide range lets manufacturers pick the best option for needs like strength, resistance to rust, or lighter weight. The foam evaporates fully with no leftover residue. This keeps the metal pure.

Industries gain from this option when making different parts, from light aluminum pieces for cars to strong iron castings for big machines. Reliable EPS pattern equipment ensures steady results across alloys.

5. Lower Global Warming Potential Compared to Traditional Methods

Environmental factors now guide many production choices, and lost foam casting provides clear benefits in sustainability. The process uses less water and energy when making foam patterns than options like green sand casting.

It also cuts metal use and waste. This reduces resource loss and disposal problems. Unbound sand in molding makes recovery and reuse simple, without binders that complicate things. Operations stay cleaner, and material costs drop.

Better accuracy leads to fewer bad castings. This further lowers scrap. The smaller overall carbon footprint supports green production goals. Lost foam becomes a smart choice for foundries that want to meet rules and company sustainability targets.

6. Broad Range of Foam Densities for Versatile Applications

Lost foam patterns allow a wide choice of densities. This increases options for different uses. Densities usually go from low to higher levels, so they can match specific casting needs.

Lower density in thinner walls cuts total weight but keeps strength. This helps reduce metal in final castings. Patterns resist common chemicals and vapors. They stay durable during handling and coating.

This range supports custom solutions for parts with internal paths, thin areas, or fine details. It works well for large production that needs uniformity, as well as special projects that require exact properties.

In summary, lost foam casting provides excellent precision, efficiency, and sustainability. It stands as a strong option for current manufacturing tasks.

OC Technology, a leading manufacturer, supplier, and factory of high-end intelligent lost foam casting equipment based in Hangzhou, China, specializes in advanced solutions that maximize these benefits. Integrating German EPS/EPP technology with independent patents, the company offers fully automatic EPS pre-expanders, shape molding machines, block molding machines, central vacuum systems, lift-type paint mixers, and complete turnkey production lines. These systems emphasize automation, energy efficiency, and high-quality output for white-area processes in lost foam casting.

Frequently Asked Questions (FAQ)

What is lost foam casting?

Lost foam casting is an evaporative pattern casting process using EPS foam patterns that vaporize upon contact with molten metal, producing precise, near-net-shape metal parts.

Which industries benefit most from lost foam casting?

Automotive, agricultural, marine, military, and heavy truck sectors commonly utilize it for complex components like engine blocks, cylinder heads, and manifolds.

How does lost foam casting reduce costs?

By minimizing machining, assembly steps, material waste, and defective parts through superior dimensional accuracy and design integration.

Is lost foam casting environmentally friendly?

Yes, it features lower energy and water use, reduced waste, easier sand recovery, and a smaller carbon footprint compared to green sand casting.

What metals work with lost foam casting?

Gray and ductile iron, aluminum, brass, and stainless steel are compatible, as long as they evaporate the foam cleanly.

Why choose advanced equipment for lost foam patterns?

High-quality machinery ensures consistent density, precision, and efficiency, critical for intricate designs and high-volume production.

Partner with a Reliable Lost Foam Equipment Manufacturer and Supplier

Foundries and manufacturers seeking to enhance lost foam casting operations require dependable, high-performance equipment. As a trusted factory and supplier, OC Technology provides cutting-edge solutions tailored for efficient, automated production lines. Contact the expert team today to discuss project needs and explore customized turnkey systems designed for superior results.