Gear manufacturing usually needs accuracy, strength, and the skill to manage complicated shapes under tough conditions. In uses like helicopter transmission test stands, gearboxes have to copy real speeds, weights, and changing forces while keeping good vibration control and solid build. Old ways to make gearbox housings, especially those with welded parts, show big problems when shapes get detailed and performance gets high.

Early gearbox designs for cars had simple parallel shafts and basic box-shaped housings. Fabricated structures worked well and saved money there. But needs changed to better systems like helicopter test stands. These need bigger sizes, more power, tricky angle setups, and strong vibration control for true test outcomes. Fabricated housings fail here because of issues in design, material sameness, weld accuracy, and stress handling.

Fabricated Gearbox Housings Weren’t up to the Task

Several basic flaws make fabricated housings unfit for advanced gearboxes:

- Mechanical design and print creation turn costly and hard for unusual shapes.

- Building housings with non-parallel sides gets tough and pricey via welding and putting parts together.

- Welded builds bring uneven material traits, which makes true structural checks difficult.

- Tight spaces in complex shapes limit full welding and sealing, risking leaks or soft spots.

- Sharp corners cause stress build-up, so extra supports or braces become needed.

- Differences in weld quality change how loads spread and how vibration acts.

- Poor or uneven welds hurt overall strength.

- Long build times, including heat treatment steps, slow down project finish.

These problems show the clear need for another method. It must give steady material traits, exact shapes, and trusted work under heavy loads.

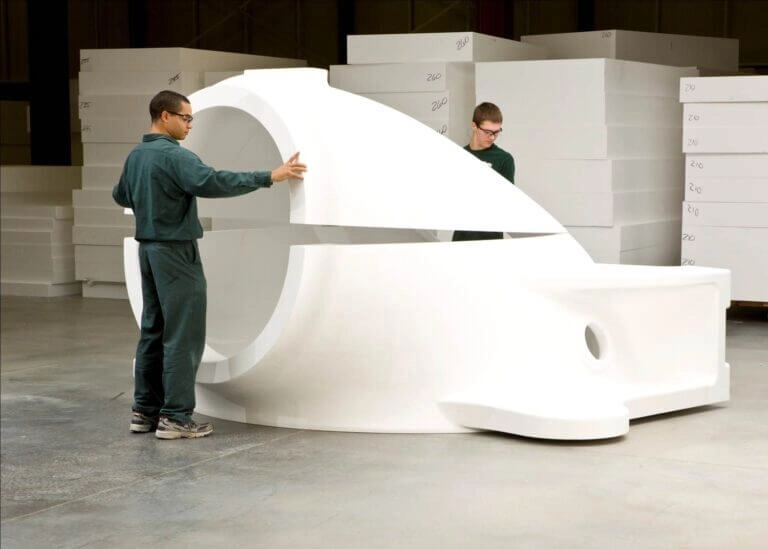

The Lost Foam Casting Process

Lost foam casting gives a better choice for making complex gearbox housings. The method starts with a foam shape made from expanded polystyrene (EPS). This shape copies the final metal piece in full detail. Workers coat the pattern with refractory material. It forms a barrier during pour and gives support. Then the coated pattern goes into loose sand inside a flask. Sand gets packed tight, and the mold stands ready for metal.

Molten metal—often ductile iron for gearbox uses—pours in. It turns the foam to vapor and fills the space exactly. The foam disappears, usually with no leftover bits. Gases slip out through the coating and sand. After cooling, the cast piece comes out, gets cleaned, and finishes.

Main steps include:

- Pattern creation: Foam is cut or shaped to fit the part design.

- Coating application: Refractory wash builds a shell like ceramic for hold and protection.

- Blocking and molding: Sand packing keeps the mold strong.

- Pouring: Controlled metal flow takes the foam’s place.

- Cooling and cleaning: Slow cooling cuts stresses. Then sand removal and surface work follow.

Ductile Iron

Ductile iron stays a top pick for gearbox housings. It offers good strength, flexibility, and steady traits. Added elements like nickel, copper, and magnesium boost its performance. The lost foam method keeps the structure even, without the changes that welding causes.

Better Stress Relief than Annealing

Cooling inside the mold brings slow temperature drop. This beats regular annealing in ovens. It leads to lower leftover stresses, less bending or cracks, and more expected material actions through the whole casting.

Design and Integration Advantages

Lost foam casting brings big freedom in design for gearbox housings. Internal spaces can form right in the cast for electronics or oil systems. Complex input/output angles fit helicopter needs. Wall thicknesses change where needed to hold bearings and direct forces. Rounded corners remove stress points and improve fatigue strength.

One-piece build makes joining easier and cuts assembly work compared to many-part welded setups.

Advanced Vibration Analysis

Vibration control matters a lot in helicopter transmission testing. The test stand must avoid adding extra noise or movements. Even material in a cast housing makes finite element checks and mode predictions simpler. Unlike fabricated ones that need weld simulation, castings let clear modeling of shape and corners to improve results.

Additive Manufacturing?

Additive manufacturing fits small parts well. But lost foam casting does better for big, heavy items weighing 5,000 to 10,000 pounds. These sizes appear often in aerospace gearbox housings. The method handles detail, size, and cost in good balance.

Final Products

Lost foam cast gearbox housings give top quality. They turn out precise, strong, and ready for dynamic uses. The approach creates parts with great vibration isolation, solid build, and safety. This makes them perfect for high-performance test stands.

FAQ

What advantages does lost foam casting offer over fabricated gearbox housings?

Lost foam casting gives steady material traits. It removes weld unevenness, cuts stress build-up, allows complex shapes without assembly trouble, and shortens build times compared to fabrication.

Why is ductile iron commonly used in lost foam casting for gearboxes?

Ductile iron mixes high strength, flexibility, and reliable mechanical traits. It handles extreme loads and changing forces in gearbox uses.

How does lost foam casting improve vibration analysis in test stand gearboxes?

The single structure allows easy modeling without weld joint checks. This leads to better guesses of natural frequencies and vibration actions.

Is lost foam casting suitable for large-scale production?

Yes, the process works well for high-volume output while keeping accuracy. This holds true especially with automated tools.

What role does the refractory coating play in lost foam casting?

The coating works as a barrier between hot metal and sand. It supports the foam pattern, guides gas escape, and helps surface finish.

Partner with a Leading Lost Foam Casting Equipment Manufacturer

Manufacturing facilities, suppliers, and factories looking to improve lost foam casting operations gain from teaming up with expert equipment providers. OC Technology, a professional manufacturer and supplier of high-end intelligent lost foam casting equipment, offers advanced solutions focused on automation, energy efficiency, and precision. As a national high-tech enterprise and partner of the China Lost Foam Industry Association, OC Technology stands out in white-area equipment. This includes fully automatic EPS shape molding machines, pre-foaming systems, energy-efficient air dryers with heat pump technology, central vacuum systems, lift-type paint mixers, maturation silos, and complete production lines for foam pattern creation and processing.

These systems support turnkey projects for foundries making complex components like gearbox housings, engine blocks, and other high-precision parts. Contact OC Technology to check customized equipment solutions that boost efficiency, quality, and sustainability in lost foam casting processes.

Visit https://www.oc-epc.com/ or https://www.oc-epc.com/contact/ for inquiries. Phone: +86 15988479417 | Email: zyh@oc-epc.com