The lost foam casting (EPC) process, also called evaporative pattern casting, is a neat way to craft detailed metal parts in the foundry world. It makes fancy shapes with hardly any waste. At the center of this method are expanded polystyrene (EPS) foam patterns. These patterns must be spot-on for great results. EPS foam plate sheet block moulding machines are super key. They create these patterns with care, speed, and reliability.

Understanding Lost Foam Casting and EPS Foam Patterns

Lost foam casting is a smart way to build complex metal pieces. It uses a foam pattern, usually made from EPS, to form the metal. First, you shape an EPS foam pattern that matches the final metal part exactly. Then, you cover it with a heat-proof coating. Next, you put it in a sand mold and pack loose sand around it. When hot metal pours in, the foam vanishes, leaving a perfect metal casting.

The EPS foam pattern’s quality is a big deal. It decides how precise, smooth, and sturdy the final casting is. For industries like cars, planes, or heavy machines, the foam needs steady thickness, exact sizes, and strong structure. EPS foam plate sheet block moulding machines are designed to make awesome foam sheets or blocks. These get carved or molded into the patterns needed for casting.

The Role of EPS Foam Plate Sheet Block Moulding Machines

EPS foam plate sheet block moulding machines are special tools. They produce EPS foam sheets or blocks with just the right traits for lost foam casting. These machines are crucial in the “white area” of the EPC process, where foam patterns are made before going to the foundry. Here’s a close-up look at what they do:

1. Precision Pattern Production

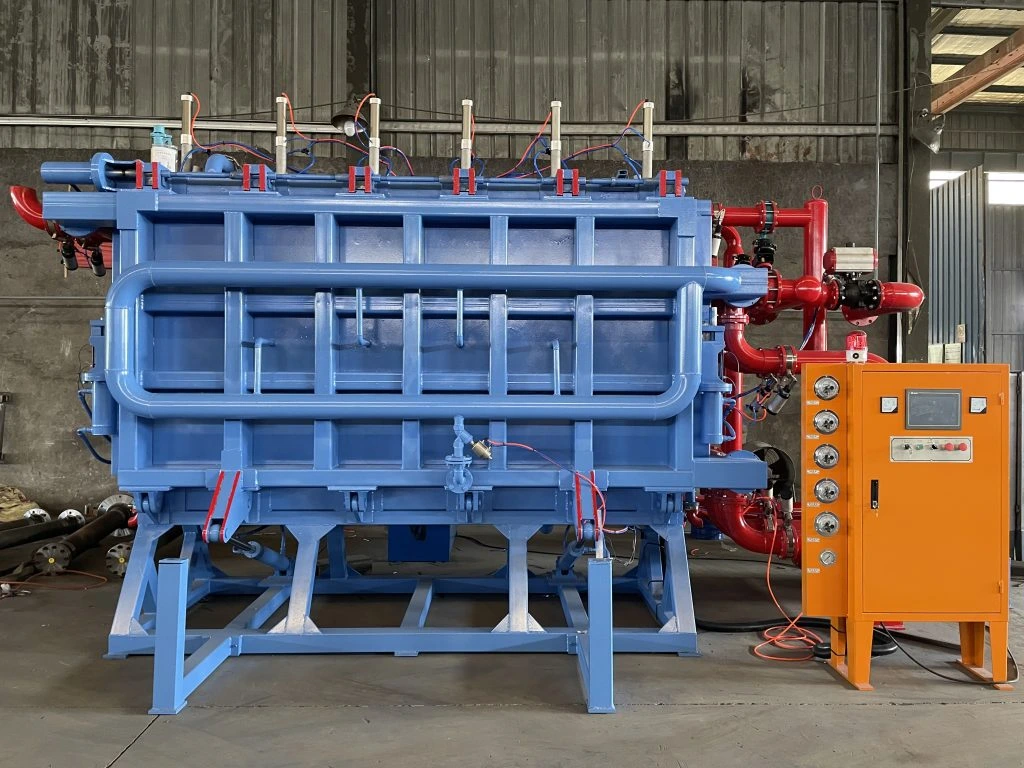

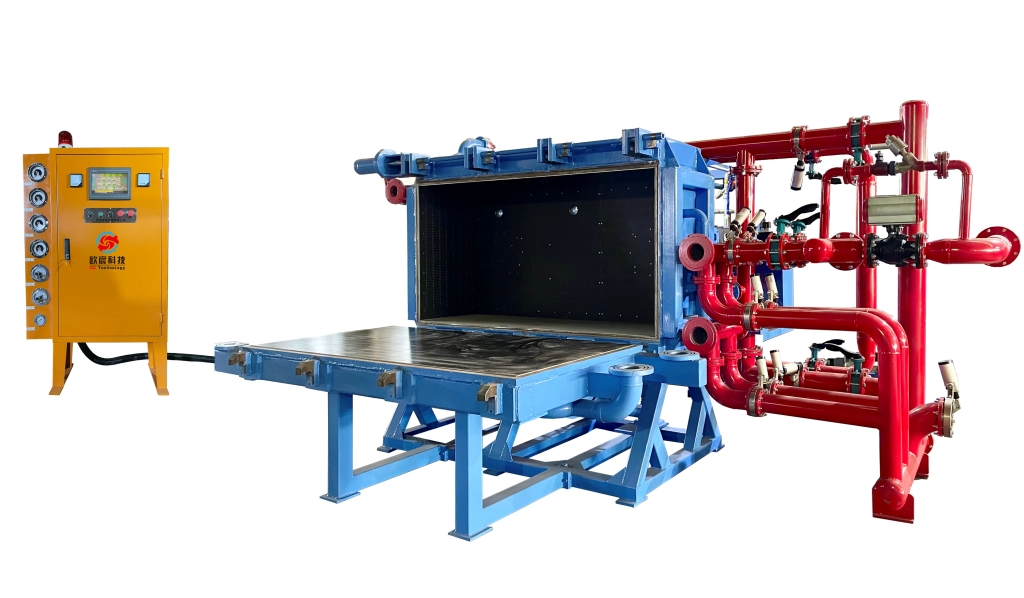

The main task of these machines is to churn out foam sheets or blocks with even thickness and perfect sizes. They let workers tweak the foam plates’ length and width to match specific needs. High-end models, like those from OC Technology, come with encoder-controlled rods and touch-screen controls. These make size adjustments a breeze. Operators just enter the sizes they want. The machine sets itself up to deliver exactly that, ensuring top-notch accuracy and ease.

2. Automation and Control Systems

Modern EPS foam moulding machines have clever control systems, like programmable logic controllers (PLCs) and touch-screen panels. These let the machines run on their own. They reduce slip-ups, cut down on breakdowns, and make maintenance simple. Some machines even have smart systems that adjust steam and heat settings automatically for the best foam. This leads to patterns with steady quality. Plus, remote control options through communication links make operations smoother and help track product quality.

3. Enhanced Process Characteristics

These machines shine because of clever design tricks. For example, OC Technology’s machines use negative pressure and fast bursts of cold air for cooling. This makes cooling twice as quick as older ways. Speedy cooling shortens production time while keeping the foam solid. Also, automatic pneumatic feeding and vacuum-assisted systems spread materials evenly. This creates foam boards with uniform density, which is vital for awesome castings.

4. High Production Efficiency

These machines are made for speed. They can work with both copolymer and EPS materials, giving lots of options. With quick feeding and cooling, they finish a foam board in 8–10 minutes. The foam plates come out with low water, great quality, and no bending. This makes them ideal for precise casting. Plus, they use less energy, which lowers costs and supports the industry’s push to be green.

5. Structural Durability and Safety

EPS foam moulding machines are built tough. OC Technology’s machines, for example, use thick square steel and strong steel plates. This makes them sturdy and resistant to warping. They have centralized hydraulic stations, single-door openings, hydraulic ejection for demolding, and auto-locking systems. These features keep things safe and efficient. Top-quality parts, like control tools, electrical bits, and pneumatic valves, ensure steady performance for years.

6. Uniform Heating for Large Patterns

Making big EPS foam patterns can be tough. You need even heating and curing. OC Technology’s machines tackle this with a unique anti-7-shaped, all-around steam drainage method. This spreads heat evenly across large foam patterns. It boosts sticking and curing, so the foam meets the strict needs of lost foam casting. This helps create big, complex metal parts with great precision.

Benefits of EPS Foam Plate Sheet Block Moulding Machines in Lost Foam Casting

Adding advanced EPS foam plate sheet block moulding machines to lost foam casting brings tons of benefits. They boost work speed, quality, and green practices:

- Great Accuracy and Quality: These machines make foam patterns with steady thickness and precise sizes. This leads to castings with smooth surfaces and exact shapes.

- Quicker Work: Fast production cycles, auto operations, and speedy cooling cut wait times. This increases how much you can produce, perfect for big orders.

- Saves Cash: Low energy use, less waste, and the option to use recycled materials lower costs. This makes lost foam casting a wallet-friendly choice.

- الاستخدام المرن: The machines work with both copolymer and EPS materials. This lets makers meet various casting needs.

- Eco-Friendly: Energy-saving designs and recycled material use support green goals. They reduce the casting process’s environmental impact.

- Safe and Reliable: Tough builds and quality parts ensure safe, steady work. This cuts downtime and repair costs.

EPS Foam Plate Sheet Block Moulding Machines Industry Applications

These machines are essential for industries that use lost foam casting to make complex metal parts. These include:

- السيارات: Crafting engine blocks, cylinder heads, and transmission parts with tricky shapes.

- الطيران والفضاء: Building light, precise parts for planes and spacecraft.

- Heavy Machinery: Making strong parts for construction and industrial gear.

- الطاقة: Creating parts for wind turbines, oil and gas tools, and power systems.

The ability to produce top-quality foam patterns with steady traits makes these machines vital for meeting these industries’ tough demands.

Why Choose OC Technology?

تكنولوجيا OC, based in Hangzhou, China, is a leading maker of smart EPS foam plate sheet block moulding machines. Sitting in China’s EPS equipment hub, the company mixes German EPS/EPP tech with its own fresh ideas. It delivers cutting-edge solutions for lost foam casting. Known as a “National High-Tech Enterprise” and a key partner of the China Lost Foam Industry Association, OC Technology is dedicated to improving automation and efficiency in the white area of EPC.

الأسئلة الشائعة

Q1: What is the role of EPS foam plate sheet block moulding machines in lost foam casting?

A: These machines create high-quality EPS foam sheets or blocks used as patterns in lost foam casting. The foam patterns are crucial for making precise, complex metal castings with little waste.

Q2: How do OC Technology’s machines ensure uniform foam pattern quality?

A: They use advanced PLC systems, vacuum-assisted feeding, and special heating methods like the anti-7-shaped steam drainage system. These ensure even density and curing.

Q3: What are the benefits of using automated EPS foam moulding machines?

A: They offer great accuracy, fast production cycles, low energy use, and the ability to use recycled materials. This leads to cost-effective and eco-friendly production.

Q4: Can these machines produce large foam patterns?

A: Yes, OC Technology’s machines handle large patterns with even heating and curing, thanks to their advanced steam drainage and heating methods.

Q5: What industries benefit from EPS foam plate sheet block moulding machines?

A: Industries like automotive, aerospace, heavy machinery, and energy rely on them to make precise foam patterns for complex metal parts.

Elevate Your Lost Foam Casting with OC Technology

Want to make your lost foam casting process quicker, more precise, and greener? OC Technology’s EPS foam plate sheet block moulding machines are the solution. With smart automation, energy-saving designs, and sturdy builds, our machines deliver top performance for industries worldwide. Contact us today to learn how we can tailor our gear to your casting needs.

- Get in Touch: Reach our expert team at +86 15988479417 or email zyh@oc-epc.com.

Transform your casting process with OC Technology’s smart, high-performance equipment. Let’s shape the future of manufacturing together!