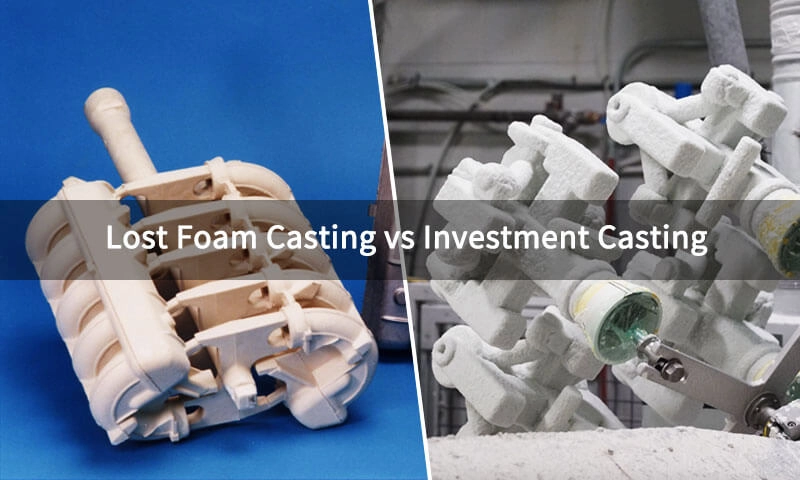

When people talk about precise ways to cast metal parts, most quickly think of investment casting. Many also call it “lost wax” casting. Yet another method exists. It is called lost foam casting. This approach stays less famous, but it brings clear benefits for some jobs. The names sound close, so workers often mix them up. This article clearly explains both methods. It shows what makes them alike and different. It also helps a manufacturer pick the right one.

What Is Lost Wax (Investment) Casting?

Lost wax casting has existed for hundreds of years. People use it to make complicated metal pieces with great accuracy. The main steps go like this:

- Wax pattern creation – Workers build an exact wax copy of the needed part.

- Shell building – They dip the wax model many times into ceramic liquid. It hardens into a strong shell.

- Wax removal – Heat melts the wax away. Only the empty ceramic shell stays behind.

- Metal pouring – Hot liquid metal flows into the hollow shell. It copies the wax shape perfectly.

- Finishing – Once the metal cools down, workers break the shell. The new part usually needs little extra work.

This way creates parts very close to final size. It gives tight measurements and smooth surfaces. Often, almost no extra cutting is required.

What Is Lost Foam Casting (Evaporative-Pattern Casting)?

Lost foam casting, also named evaporative pattern casting or EPC, works with a different starting material. Workers shape the part from light expanded polystyrene (EPS) foam instead of wax:

- Foam pattern – The part shape comes from cheap, lightweight EPS foam.

- Coating – A heat-resistant slurry covers the foam completely.

- Molding – The coated foam sits inside loose, unbonded sand for support.

- Pouring – Hot metal pours straight onto the foam. The foam quickly turns to gas and disappears. Metal fills the space exactly.

- Finishing – Some light machining might still happen after cooling.

This process handles tricky shapes well. It often costs less, mainly for bigger or detailed pieces.

Similarities Between the Two Processes

Even though the materials and some steps differ, these two methods share important points:

- Both start with a disposable pattern (wax or foam) that sets the final metal shape.

- Each can form highly complex and detailed parts that other casting ways struggle with.

- They work with many metals, both ferrous and non-ferrous types.

- Finished parts usually need very little extra machining because the pattern is accurate.

- Tight measurements are possible, so both fit high-precision work.

Key Differences Between Investment Casting and Lost Foam Casting

The basic idea looks close, yet real differences appear in daily use:

مادة نمط

Investment casting starts with wax that workers must melt or burn out first. Lost foam casting uses EPS foam that simply vanishes when hot metal touches it.

Process Complexity & Steps

Investment casting needs many careful stages, including shell making and wax removal. Lost foam casting skips those extra stages. The foam leaves on its own during pouring.

الانتهاء من السطح

Investment casting gives smoother surfaces and sharper small details. Lost foam casting often leaves a slightly rougher texture. Extra polishing may be needed.

Tooling Costs

Wax tooling for investment casting can cost a lot upfront. Lost foam patterns are usually cheaper to make, though special equipment can add expense at larger volumes.

Energy and Material Efficiency

Investment casting reuses wax carefully but still creates some waste. Lost foam casting burns away the foam, creating little solid waste if fumes are controlled properly.

Scale & Applications

Investment casting shines for small-to-medium parts that need perfect finish, such as aerospace, medical, or jewelry items. Lost foam casting fits larger industrial pieces where lower tooling cost and faster flow matter more.

Why Choose One Over the Other?

The best choice depends on what matters most to the factory:

- Production volume: Large runs often favor lost foam because tooling pays off quickly.

- Part complexity: Both manage hard shapes, yet investment casting wins for tiny details.

- Surface requirements: Very smooth or decorative finish points to investment casting.

- Budget constraints: Lost foam casting can save money on certain sizes and shapes.

- Sustainability: Foam that evaporates can mean less solid trash if the system captures gases well.

- Lead times: Fewer steps in lost foam casting sometimes speed up delivery.

OC Technology’s Role in Lost Foam Casting Innovation

تكنولوجيا OC, stands as a leading manufacturer of modern lost foam casting (EPC) equipment. It builds fast, automated machines for the lost foam industry. OC Technology mixes German EPS/EPP know-how with its own patented ideas. Quality, energy saving, and automation stay at the center of every design.

Some key products include:

- Fully automatic vacuum EPS pre-expander machines (e.g., models OC-YF-Y450 and OC-YF-Y550) with PLC control, mixed steam foaming, and exact weighing for steady bead quality.

- Horizontal and vertical foam molding machines that shape patterns reliably.

- Maturation silos with anti-static features and sensors for perfect bead ripening.

- Central vacuum systems, air dryers, and bonding machines that complete the production line.

OC Technology has finished projects worldwide, such as Cairo Foundry Company in Egypt and tractor or aluminum factories. The company earned national high-tech enterprise status and works closely with the China Lost Mold Industry Association.

When Lost Foam Casting Beats Investment Casting — from a Manufacturing Perspective

For many factories, lost foam casting (with good machines) wins in these cases:

- Making big, complicated parts for heavy machines, trucks, or large housings.

- Getting good enough accuracy and shape without paying for the super-smooth finish of investment casting.

- Cutting down waste because the foam simply turns to gas.

- Growing production easily with automated pre-expander and molding systems from OC Technology that lower labor and keep quality steady.

- Meeting green goals thanks to energy-saving machines that still run fast.

الأسئلة الشائعة

Q1: Is lost foam casting the same as investment casting?

No. Both use a pattern that disappears, but lost foam casting burns away EPS foam during pouring while investment casting melts wax out first.

Q2: Which process gives a better surface finish?

Investment casting normally creates smoother, cleaner surfaces. Lost foam casting might need extra work for the same result.

Q3: Are the tooling costs higher for lost foam casting or investment casting?

It varies. Wax tooling for investment casting is often costly. Foam patterns can be cheaper, but modern automated equipment also carries a price.

Q4: How does OC Technology support the lost foam casting process?

OC Technology builds complete automated equipment lines, including pre-expanders, foam molding machines, maturation silos, vacuum systems, and bonding machines.

Partner with OC Technology — Your Trusted EPC (Lost Foam Casting) Equipment Supplier

Foundries that want dependable, modern equipment should look at OC Technology (Hangzhou Ouchen Technology Co., Ltd.). Their advanced EPC machines raise speed, accuracy, and green performance. The main products cover:

- Fully automatic vacuum EPS pre-expander machines (e.g., OC-YF-Y450, Y550)

- Vertical and horizontal foam molding machines

- Maturation silos with anti-static design

- Central vacuum systems, air dryers, and hot-melt foam bonding machines

Working with OC Technology helps factories grow output, cut labor cost, and keep quality high. For full turnkey EPC solutions or to visit the plant, reach out على 86 15988479417 أو البريد الإلكتروني zyh@oc-epc.com. More information waits at the official site: oc-epc.com.