Lost-foam casting, often called evaporative pattern casting (EPC), stands as a clever metal shaping method. It brings sharp detail and quick work for tricky parts. The method caught on in factories during the 1980s, mostly in car making. General Motors started using it in 1986 for aluminum engine blocks, cylinder heads, iron crankshafts, and differential cases in the Saturn models. Now, big makers like PSA (Peugeot, Citroën, Opel, and Vauxhall) depend on lost-foam casting for engine pieces. This shows its lasting value in large-scale output.

This way mixes bits from investment (lost-wax) and sand casting. Investment casting uses wax shapes that melt away before metal goes in. Yet, lost-foam casting applies expanded polystyrene (EPS) foam shapes. These vanish from the hot molten metal as the mold gets full. It acts like sand casting with loose sand for the mold, but no sticky binders. That keeps things tidy and easy to reuse. The outcome? Detailed items need little fix-up after. They suit fields that want lost foam casting equipment and smart machines.

For workshops that need steady lost foam casting answers, teaming with a focused manufacturer like OC Technology gives entry to top EPC tools. As a top China lost foam casting equipment supplier, OC Technology offers auto setups. These improve each stage, from foam shape making to metal flow. They cut flaws and raise speed.

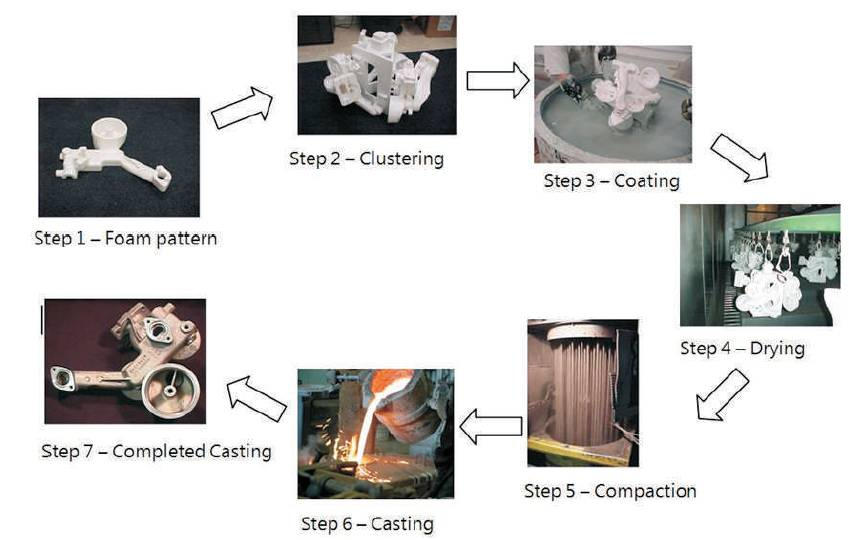

The lost-foam casting process

Lost-foam patternmaking

The path starts by building EPS foam shapes. These form the base for exact lost foam casting. Tiny pre-grown polystyrene beads go into aluminum forms under warmth. They swell and stick together to shape the pattern. Then cooling happens. It lets removal and resting—often days in normal air or hours in a warm room—to steady sizes and handle shrink.

Shape truth matters most. It sets how close the end casting matches. Soft EPS needs careful touch to stop bends. Thickness finds a middle: low for smooth metal run but maybe rough look, high for toughness but hard on slim areas. For tough mixes like high-carbon ductile irons, usual EPS brought shiny carbon flaw risks. Now EPS-PMMA mixes come in—OC Technology’s better stuff burns off neat, no left bits. This opens use in hard fields.

As a reliable lost foam casting factory, OC Technology’s máquinas de prefoaming y foam molding equipment ease this part. They keep steady bead growth and shape strength for big output.

Assembling the patterns

After resting, shapes get stuck into many-piece groups for hard forms. This limits glue push-out to skip surface marks. Groups build around a main “tree” for lot casting small items; big ones go alone. A hard ceramic cover locks the shape. It adds firmness and holes for gas out.

OC Technology’s auto coating spots and air dryers fit right in here. They use power-saving heat pumps to dry shapes without twists. This proves key for busy lost foam casting lines.

Coatings and sand investment

Covers do two jobs: guard from sand-metal touch and guide gas leave. For iron items (hot), open-mix types handle fast gas push to stop push-back. In aluminum (cool), they take in polymer bits quick. This stops run errors or swirl flaws like air pockets.

Sand—big, round, and smooth-flow—packs the steel box around the covered shape. Shakes tight it without harm. It fills space (just gravity help). No binders mean simple take-back. This fits green lost foam casting ways.

OC Technology’s shake tables and sand move systems better this. They push even tight for no-flaw molds.

Filling and shake-out

Hot metal flows straight for aluminum through open covers; iron often takes bottom gates or suck for guide. After hard, boxes tip on belts for shake-out. They get back 95%+ sand. Cut from trees, items need little cut thanks to great looks.

OC Technology’s suck-help pour gear boosts size truth. It makes them the top pick for iron and non-iron lost foam casting auto.

What is lost-foam casting used for?

Lost-foam casting shines in car, plane, and machine work. It makes engine blocks, pump shells, and gears from metals like aluminum, iron, and steel. Its flex fits test pieces to big lots. OC Technology’s gear lets world workshops build hard parts fast.

APPLICATION AREAS OF LOST-FOAM CASTING

· Automotive: Engine parts, gear boxes—sharp cuts weight and join steps.

· Machinery: Valves, shells—tricky insides without inserts.

· Aerospace: Light build pieces—top truth cuts scrap.

· General Manufacturing: Special tests—works for low-to-mid counts.

OC Technology drives these with fit lost foam casting equipment, from pre-foamers to shape lines.

ADVANTAGES AND DISADVANTAGES

Advantages of lost-foam casting

· Great size truth and smooth look—no extra edges or split marks.

· Allows hard forms without inserts or sticks.

· Less cut, smooth, and scrap stuff.

· Flex sizes (0.5kg to tens of kg) and metal match.

· Green: Reuse sand, less power.

Disadvantages of lost-foam casting

· Weaker item strength in some mixes.

· Foam shapes easy hurt by touch.

· Needs tight guide to skip gas flaws.

Even with issues, new steps from suppliers like OC Technology ease them. They give strong EPC answers.

RECOMMENDED PRODUCTS

For best lost-foam casting, look at OC Technology’s set:

· Foam Molding Machines: Auto for exact EPS shapes.

· Pre-Foaming Machines: Steady bead swell.

· Air Dryers: Power-smart dry to stop flaws.

· Coating & Vibration Systems: Joined for smooth pack.

· Full EPC Lines: Ready auto for full flow.

As a national high-tech enterprise, OC Technology gives these with world help. It cuts make time and costs.

PREGUNTAS FRECUENTES

What is lost-foam casting, and how does it differ from sand casting?

Lost-foam casting uses EPS foam shapes that burn off in pour. Traditional sand casting has hard molds and binders. This gives smoother looks and hard forms with loose sand for easy reuse.

What are the main advantages of lost-foam casting for manufacturers?

It offers close-net shape truth, little after-work, and form choice. This trims costs by up to 30% in car uses and backs green ways.

Can lost-foam casting handle high-volume production?

Yes, with auto gear like OC Technology’s systems, it grows from tests to big runs. It suits OEMs in iron and non-iron metals.

What materials are best for lost-foam casting?

Aluminum, grey/ductile iron, and steel work well; EPS-PMMA mixes boost match for no-flaw results in high-carbon mixes.

How can foundries source reliable lost-foam casting equipment?

Team with set suppliers like OC Technology for custom, high-tech answers with years of EPC know.

Partner with OC Technology: Empower Your Foundry as a Leading EPC Equipment Manufacturer and Supplier

As a top lost foam casting equipment manufacturer, supplier, and factory, OC Technology brings fresh EPC answers fit for workshops around the world. If you grow output or better auto, our new machines—from pre-foamers to full casting lines—push speed, truth, and green.

Ready to change your work? Reach our skilled group now al 86 15988479417 o correo electrónico zyh@oc-epc.com for free talk. Let’s work to build lost-foam casting future—ask your fit quote today and open top make power!