What is Lost-Foam Casting?

Casting de espuma perdida is as close as you can get to manufacturing “magic”—the way it can transform a delicate foam model into a solid metal item with almost unreal precision is practically sorcery. Also going by the names evaporative casting and the expanded polystyrene process, lost-foam casting is a technique that involves using expanded polystyrene foam as a mold that shapes molten metal and evaporates when it’s done. It came about in the late 1950s and is still a popular method today for both manufacturers and intrigued hobbyists.

The Lost-Foam Casting Process

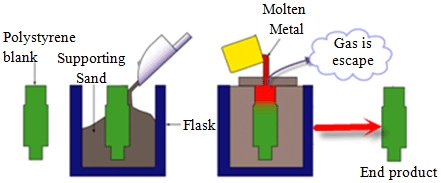

Step-by-Step Overview of the Process

Pattern Creation Using Foam

First, the foam molds are prepared. These are in the shape of the intended finished product and they get filled through a gating system with passages that allow for precise design specs.

At this stage, Hangzhou Ouchen Technology Co., Ltd provides essential equipment such as the Foam Block Machine and Máquina de prefoaming. The foaming method is a mixture of electromagnetic and steam foaming, using electromagnetic heating to stabilize the temperature of the barrel at 98 degrees.

Assembly of Foam Patterns into Trees

Next, you bond the foam pattern or mold to the gating mechanism to make sure the alignment is spot on. This step forms an assembly known as a “foam tree,” which includes runners and risers necessary for metal flow.

Coating with Ceramic Slurry

Then you’ll apply dip paint, which, when dry, creates a ceramic coating on your mold, boosting its toughness, heat resistance, and ability to handle the high temperatures of the metal. Hangzhou Ouchen’s Lift Type Paint Mixer plays a crucial role here. Under the high-speed rotating blade cutting, the coating is delicate and non foaming, and its coating and leveling properties are greatly superior to traditional coating mixers.

Drying and Compaction in Sand Mold

Once this is done, you’ll place the mold and gating mechanism (which are now one piece) into a bucket, container, or vessel of dry sand. This holds your piece in place and keeps it in the right position during casting. After filling with sand, the container will go through vibration to make sure that the sand fully encompasses the module.

Metal Pouring and Foam Vaporization

This is when the molten metal gets poured into the mold. The heat of this makes the mold vaporize (sorcery!), leaving room for the metal to fill in and form. Finally, after the molds have cooled, they’ll go through cleaning and finishing. You can also recycle the sand.

Materials Used in Lost-Foam Casting

Suitable Metals and Alloys

Steels and stainless steels: These alloys are popular for melting down and pouring into the mold because they’re strong and very resistant to corrosion.

Aluminum alloys: These are often pretty affordable materials when used for lost-foam casting. Because they’re lightweight, strong, and thermally conductive

Cast irons: Whether gray or ductile, cast iron is strong and resistant to wear

Nickel alloys: Thanks to how well they can handle heat and corrosive environments

Types of Foams and Coatings Employed

The pattern for the item you’re looking to make is cut from a foam block and coated in ceramic or another covering. The foam used typically consists of expanded polystyrene (EPS), while coatings are ceramic-based slurries designed for thermal resistance.

Application Areas of Lost-Foam Casting

When you want an intricate or complex part with thinner walls or perhaps inner channels, you can look to lost-foam casting to get the job done. You’ll find cylinder heads, engine blocks, cooling system housings, and other engineered parts made in this way.

Lost-foam casting allows for the creation of highly complex, near-net-shape parts with intricate geometries that would be difficult or impossible to achieve using traditional casting methods

Ventajas y desventajas

Key Benefits of Lost-Foam Casting

It’s a top-notch choice for creating precise parts with specific dimensions

Because of the way it works, it also avoids flash

This advantage translates into real-world applications such as lightweight automotive engine components reducing machining costs and material waste while enabling innovative designs.

Limitations and Challenges of the Process

The disadvantages of lost-foam casting tend to be the cost of the die (if you’re using a closed-die molding method) and a higher level of porosity in your castings.

You also might find that patterns or molds tend to get damaged more easily.

Hangzhou Ouchen equipments for lost-foam casting foundries

Hangzhou Ouchen Technology Co., LTD specializes in high-end intelligent equipment tailored specifically for lost-foam casting white area processes. The company introduces German EPS/EPP top technology combined with a number of independent intellectual property patents

Foam block Machine

The Foam block Machine adjusts plate size from length and width according to customer requirements The equipment will automatically adjust size via touch screen input. It is easy to operate

Máquina de prefoaming

The foaming process uses electromagnetic heating to maintain barrel temperature at 98°C avoiding dead beads production while ensuring smooth spherical surfaces without rupture.

Silo de maduración

Due to negative pressure inside newly prepared beads they need maturation time (8–12 hours) so air enters gradually balancing internal pressure before molding expansion occurs effectively.

Máquina de moldeo de espuma

PLC computer control automatically completes each molding process establishing parameter databases for quality traceability across white mold batches during production cycles.

Sistema de aspiración central

The central vacuum unit adopts PLC automatic control maintaining vacuum pressure between -0.5MPa ~ -0.8MPa ensuring quick cooling with low moisture content on demolded white molds without deformation or bulging surface defects.

Mezclador de pintura tipo elevador

The paint mixer consists of main disperser & mobile anti-sedimentation immersion tank High-speed mixing motor ensures fine dispersion without foaming enhancing coating properties significantly over traditional mixers.

Secador de aire

Drying systems integrated within Hangzhou Ouchen’s workflow ensure all coated foam patterns are thoroughly dried before sand compaction—critical for successful metal infiltration during pouring.

Lost-foam casting remains an advanced yet accessible solution across industries seeking precision-engineered components. With companies like Hangzhou Ouchen delivering full-process automation equipment—ranging from pre-expansion through vacuum-assisted molding—they empower foundries globally toward efficiency-driven innovation in metal casting technology. Contacto Hangzhou Ouchen today.