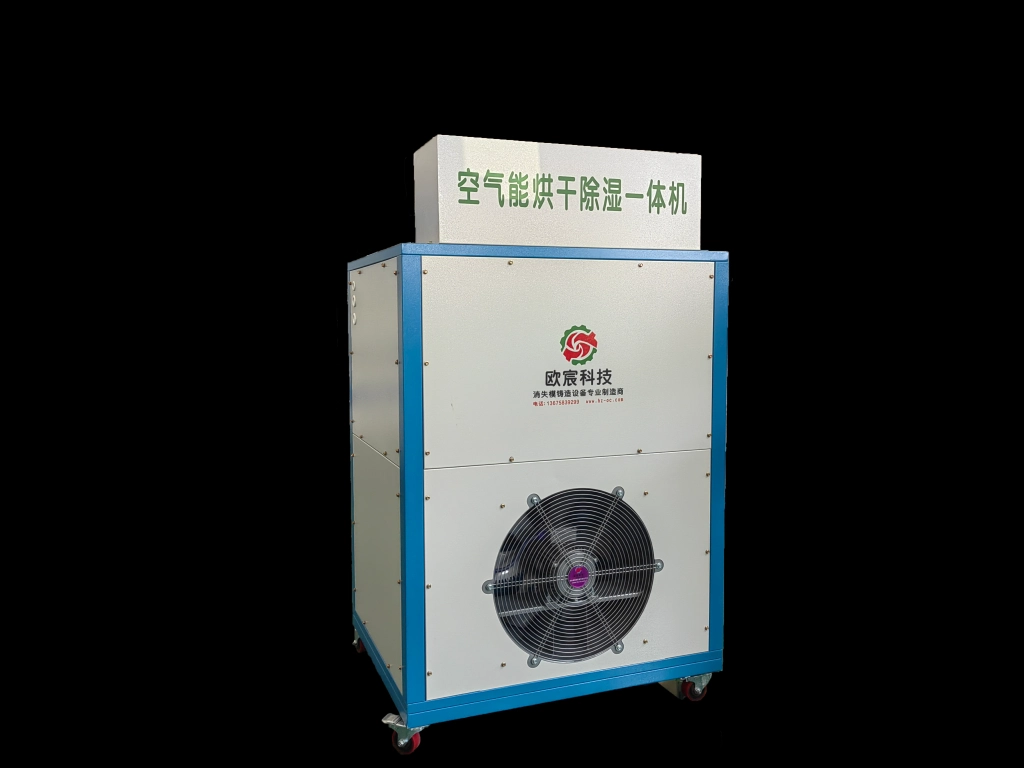

Lost foam casting is a common way to make exact metal pieces. Foundries need trusty equipmentएस to do it right. One important equipment is the indoor air dryer. It has a big job in getting good results. Drying matters after coating the white molds and before casting. It removes water that could cause problems. हांग्जो ओचेन टेक्नोलॉजी कं, लिमिटेड is a top company in lost foam casting equipments. They offer modern indoor air dryers. These help foundries work fast, keep quality high, and be eco-friendly. This article explains why indoor air dryers are needed in today’s foundries. It also shows how they work in the lost foam casting process.

Understanding the Lost Foam Casting Process and the Role of Indoor Air Dryers

Lost foam casting is a process with many steps. It turns raw stuff into detailed metal pieces. First, a foaming machine makes raw stuff into beads. These beads go into a maturation silo. The silo balances their pressure inside. Next, a forming machine shapes the beads into white molds. A central vacuum system cools the molds. It takes away heat and wastewater. The molds get dried again before casting. Then, a paint mixer puts a coating on the molds. An indoor air dryer takes water out of the coated molds. The indoor air dryer is key in the drying steps. It makes sure the molds have no water for perfect casting.

Why Drying Matters in Lost Foam Casting

Drying is a big deal in lost foam casting. Water in the white molds can cause issues. If molds aren’t dried well, they might crack or bulge. They may not join right during casting. This makes faulty pieces and wastes stuff. An indoor air dryer takes out water well. It keeps molds smooth and strong. By keeping water levels low, the indoor air dryer helps foundries make top-notch metal pieces. It causes fewer mistakes. This saves time and money.

Benefits of Using Indoor Air Dryers in Foundries

Indoor air dryers give many perks to foundries. They are a wise pick for lost foam casting. They save power, help nature, and keep quality steady. Companies like Hangzhou Ouchen Technology Co., LTD make their indoor air dryers with cool features. These include heat pump technology and smart controls. They make the benefits even better.

Energy Efficiency with Indoor Air Dryers

Power costs worry foundries a lot. Indoor air dryers help keep these costs down. They use heat pump technology to turn room air into hot air for drying. This uses less power than old ways. Also, the indoor air dryer grabs waste heat from the casting process. It reuses it. This cuts power use even more. This smart design lowers bills. It makes foundry work more budget-friendly.

Environmental Sustainability

Foundries get pressure to harm nature less. Indoor air dryers help reach this goal. They make zero emissions while running. This makes them a green pick. The indoor air dryer uses a closed-loop system. It grabs heat and stops wastewater. This shrinks the foundry’s eco-footprint. By picking an indoor air dryer, foundries can work in an eco-friendly way. They also meet industry rules.

Consistent Drying Quality

Top-notch drying is key for perfect white molds. The indoor air dryer from Ouchen keeps exact temperature control. It stays within ±1°C. This makes drying even for all molds. It stops warping or surface problems. With steady drying, foundries can trust the indoor air dryer. It gives smooth, problem-free molds every time. This boosts overall product quality.

How Indoor Air Dryers Enhance Foundry Operations

Indoor air dryers do more than dry molds. They make the whole foundry better. They automate tasks, save workers’ time, and work well with other equipments. Ouchen’s indoor air dryers are made to make foundry work simpler and faster.

Automation and Labor Savings with Indoor Air Dryers

Today’s foundries need equipments that cut handwork. The indoor air dryer does this. It has automatic temperature controls and set drying curves. So, workers don’t need to watch it all the time. One worker can handle many drying rooms. This saves labor costs. This automation also cuts mistakes. It makes the indoor air dryer a great equipment for busy foundries.

Customizable Drying Solutions

Every foundry has different needs. The indoor air dryer can be changed to fit them. Ouchen’s dryers let you adjust temperature, humidity, and airflow. This suits different mold sizes and materials. This flexibility gives the best drying for any job, big or small. With a customizable indoor air dryer, foundries can handle all kinds of production needs easily.

Integration with Lost Foam Casting Lines

An indoor air dryer works best when it fits with other casting equipments. Ouchen’s dryers connect well with their central vacuum system and paint mixer. This makes a smooth process for molding, coating, and drying. The indoor air dryer’s heat recovery system reuses energy from the molding step. This boosts efficiency. This teamwork makes the whole casting line quicker and more trusty.

Addressing Common Foundry Concerns About Indoor Air Dryers

Foundries often ask about new equipments. They wonder about costs, upkeep, and growth. Indoor air dryers solve these worries with practical answers. This makes them a trusted pick for lost foam casting.

Are Indoor Air Dryers Cost-Effective?

Indoor air dryers cost money upfront. But they save cash over time. Their power-saving design cuts utility bills. Automation lowers labor costs. Fewer casting problems mean less waste. This saves more money. Ouchen’s indoor air dryers use strong materials. They need fewer repairs. This makes them a budget-friendly pick.

Maintenance and Durability

Foundries need equipments that last. The indoor air dryer is built tough. It uses high-quality parts and sturdy materials. It handles heavy use. Simple upkeep, like checking filters and cleaning ducts, keeps it running well. With good care, the indoor air dryer works reliably for years.

Scalability for Growing Foundries

As foundries grow, their equipments must keep up. The indoor air dryer can handle this. It works for small and big production amounts. Ouchen offers customizable options. They fit a foundry’s needs, from small units for new businesses to big systems for large operations. This scalability lets the indoor air dryer grow with the business.

Conclusion: Elevate Your Foundry with Indoor Air Dryers

Indoor air dryers change lost foam casting for the better. They save power, keep quality steady, and help nature. They make work smoother, cut costs, and ensure top-notch molds. They are key for modern foundries. Hangzhou Ouchen Technology Co., LTD offers modern indoor air dryers and other lost foam casting equipments. They help foundries do well. To learn more about how an indoor air dryer can improve your production line, contact Ouchen +86 15988479417 पर या zyh@oc-epc.com. You can also visit https://www.oc-epc.com/ for details.