Understanding EPS Foam Block Machines

What Are EPS Foam Block Machines?

EPS foam block machines are industrial systems designed to produce expanded polystyrene (EPS) blocks, which serve as the foundational material for various applications, including lost foam casting. These machines are engineered to expand raw polystyrene beads and mold them into large, uniform blocks through a controlled heating and molding process. The resulting foam blocks are lightweight, rigid, and easily machinable, making them ideal for creating complex casting patterns.

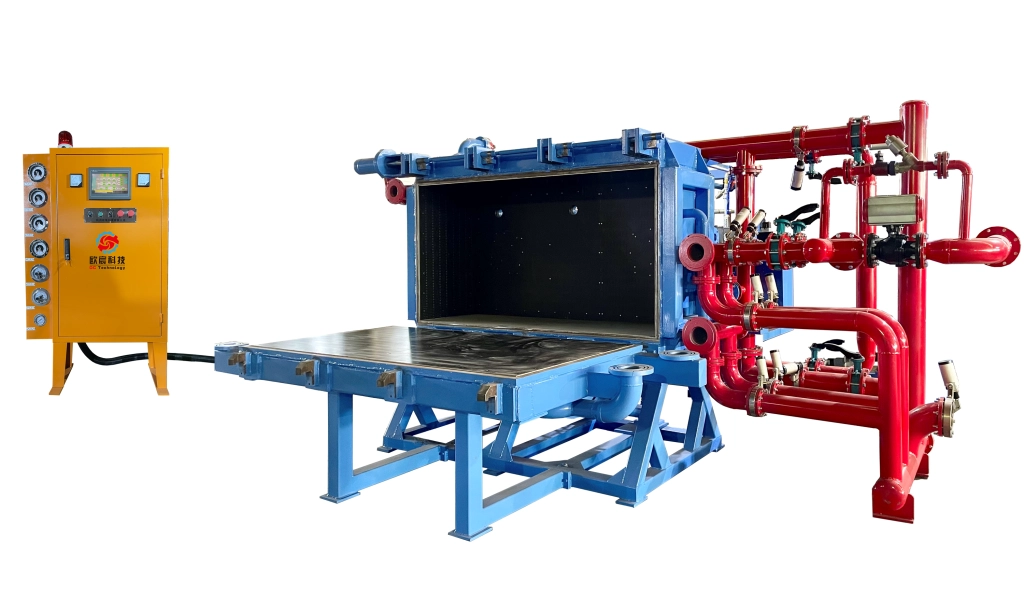

img.EPS foam block machines

Key Components and Working Principles

An EPS foam block machine typically includes several integrated systems: a pre-foaming unit, a molding chamber, a steam control system, and a cooling mechanism. Adopting PLC programmable controller and touch screen control, fully automated operating system, low failure rate, easy maintenance. The molding process is enhanced with advanced features like vacuum-assisted feeding and automated hydraulic demolding. Fully automatic pneumatic feeding, vacuum assisted feeding, ensuring consistency in board density.

The heating process uses steam to expand the beads uniformly inside the mold. The exclusive design of the anti 7-shaped and all-round dispersion sequence steam drainage penetration heating method solves the problem of uniform heating temperature for large-sized disappearing template materials, ensuring even curing and strong adhesion across the block.

The Role of EPS Foam Blocks in Lost Foam Casting

Why EPS Is Ideal for Lost Foam Patterns

EPS is highly suitable for lost foam casting due to its unique physical properties. It is lightweight yet structurally stable enough to maintain shape under moderate pressure. Most importantly, it vaporizes cleanly when molten metal is poured into the mold cavity during casting, leaving behind no residue that could compromise the final metal part’s integrity.

How EPS Blocks Are Shaped and Molded for Casting Use

Once produced by an EPS foam block machine, the blocks are cut or CNC-machined into precise shapes that replicate the final cast product. These patterns are then assembled into clusters if needed and coated with refractory materials before being placed into sand molds. The dimensional stability of high-quality EPS blocks ensures that these patterns retain their geometry during handling and casting.

Advantages of Using EPS in Foundry Applications

Using EPS in foundry applications offers numerous benefits:

- Excellent dimensional accuracy

- Simplified mold-making process

- Reduced need for parting lines or cores

- Clean burnout with minimal environmental impact

These advantages make EPS indispensable in modern foundries employing lost foam casting techniques.

How EPS Foam Block Machines Improve the Lost Foam Casting Process

img.EPS foam block machines for lost foam casting

Enhancing Pattern Accuracy and Consistency

EPS foam block machines contribute significantly to pattern precision by producing uniform-density blocks that ensure consistent expansion and shaping. The produced foam plate has low water content, high quality and no deformation. This uniformity minimizes defects in casting patterns caused by density variations or warping.

Reducing Material Waste and Production Costs

Modern machines incorporate automation technologies such as touch-screen interfaces and programmable logic controllers (PLCs), allowing precise control over material input and processing parameters. The customer only needs to input the adjustment number on the touch screen, and the equipment will automatically adjust the size. It is easy to operate. This reduces waste from over-expansion or misformed blocks while optimizing energy use.

Additionally, the advanced material and post adjustment process can be selected to greatly improve the mixing ratio of recycled materials, helping reduce raw material costs without compromising product quality.

Supporting Complex Geometry and Design Flexibility

Because EPS can be easily machined or molded into intricate shapes, it supports high design flexibility. High-quality foam from advanced machines ensures that even complex geometries remain intact during handling. This capability allows foundries to produce parts with internal channels or detailed surface textures without additional tooling.

Common Questions About EPS Foam Block Machines for Lost Foam Casting

What Is the Best Density of EPS for Lost Foam Casting?

The optimal density varies depending on part size and complexity but typically ranges from 15 kg/m³ to 30 kg/m³. Lower densities may suffice for small components while larger or more detailed parts require higher densities for structural integrity during coating and casting.

How Long Does It Take to Produce an EPS Pattern?

Production time depends on machine speed, pattern complexity, and batch size. However, the production cycle of each foam board is 8-10 minutes, meaning multiple patterns can be created within an hour using efficient machinery setups.

Can EPS Foam Block Machines Handle Large-Scale Production?

Yes. Industrial-grade machines are designed for high output rates with features such as continuous feeding systems and automated demolding cycles. One time molding, optional conveyor belt for unmanned and automatic cyclic production. These capabilities make them ideal for mass-producing patterns in automotive or aerospace sectors.

What Maintenance Is Required for These Machines?

Routine maintenance involves checking hydraulic systems, cleaning steam lines, inspecting molds for wear or damage, calibrating sensors/controllers regularly, and ensuring proper lubrication of moving parts. Fortunately,fully automated operating system[s have] low failure rate [and are] easy [to] maintain.

How Do I Choose the Right Machine for My Foundry?

Key considerations include required block dimensions, output volume per shift/day/month, compatibility with existing CNC cutting tools or coating stations, energy efficiency ratings, support options from manufacturers like Hangzhou Ouchen Technology Co., Ltd., which specializes in lost foam area equipment.

Technological Advancements in EPS Foam Block Machinery

Recent innovations include adaptive servo-controlled steam systems that adjust pressure based on real-time feedback,an optional expert control system can be selected to achieve adaptive proportional servo adjustment of steam volume and heating temperature. Remote monitoring capabilities also allow operators to track performance metrics offsite.A communication interface is set up to remotely control equipment operation and product quality.

Other advancements include integration with conveyor belts for seamless production cycles,optional conveyor belt for unmanned and automatic cyclic production, further reducing labor requirements while increasing throughput.

Factors to Consider When Investing in an EPS Foam Block Machine

Machine Capacity and Output Requirements

Evaluate your foundry’s daily production targets against machine specifications like mold cavity size per cycle time.High production efficiency ensures you meet demand without unnecessary capital expenditure on oversized equipment.

Compatibility with Existing Foundry Equipment

Ensure your new machine integrates smoothly with current CNC routers or coating booths used downstream in pattern preparation workflows. Check whether electrical/pneumatic components meet your factory standards.The control instrumentsused are all high-quality branded products at home and abroad, ensuring reliable performance across diverse setups.

Industry Applications Beyond Traditional Foundries

Automotive Part Manufacturing Using Lost Foam Casting

Automotive manufacturers use lost foam casting extensively to produce engine blocks, intake manifolds, transmission cases—components requiring fine detail replication at scale made possible through precision-machined EPS patterns from block machines.

Aerospace Component Fabrication with EPS Patterns

In aerospace industries where weight-to-strength ratios are critical, aluminum castings made via lost foam methods benefit from ultra-lightweight yet dimensionally accurate EPS cores shaped using advanced block machinery.

Use in Artistic and Architectural Metalwork

Artists creating large-scale metal sculptures often rely on custom-carved EPS forms as templates before bronze casting; similarly architects use it when designing decorative metal panels requiring intricate geometric motifs—both made feasible by precise cutting of uniformly dense blocks produced by quality machines.

buy your EPS Foam Block Machines from Hangzhou Ouchen

Hangzhou Ouchen Technology Co., Ltd. is a company specializing in the production of high-end intelligent lost foam area equipment. Located in Xindeng Town of Hangzhou City’s Fuyang District,the body is made of thickened square steelwith high strengthand sturdy durability.

Their offerings feature intelligent controls,adopting PLC programmable controllerlow failure rateeasy maintenance, energy-efficient designs,low energy consumptionlow cost in the production process, as well as remote operation interfaces—all backed by responsive support channels via phone (+86 15988479417) or email (zyh@oc-epc.com).

For foundries seeking dependable performance combined with technological sophistication in their lost foam operations—Hangzhou Ouchen remains a premier choice.