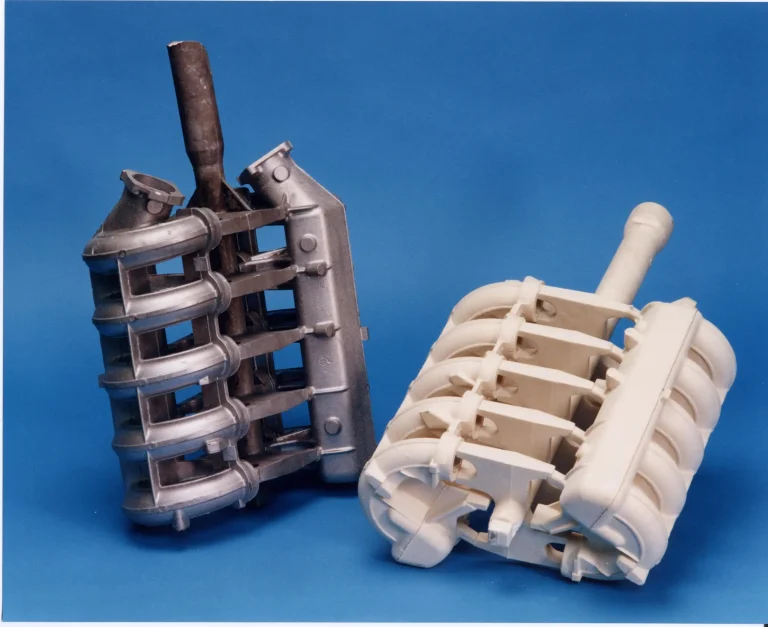

What is the Lost Foam Casting Process

Lost Foam Casting is a cool way to make detailed metal parts. It uses a foam shape to create exact castings. A foam model gets coated with heat-proof material. Then, it’s placed in loose sand. When hot metal is poured, the foam burns away. This leaves a space that fills with metal to form the part. This method gives sharp sizes, needs less machining, and makes fancy shapes cheaply.

The Role of Thermal Management in Lost Foam Casting

Importance of Consistent Heating and Cooling Cycles

Keeping heat steady is super important in lost foam casting. Even heating and cooling keep materials from twisting or shrinking wrong. Any mix-up can cause flaws like warped parts or empty mold spots. A steady heat setup also helps dry molds well, which is key for great castings.

Impact of Temperature Fluctuations on Casting Quality

Changes in heat can harm the strength of cast parts. Uneven heat might make metal harden too soon or trap gas, causing weak spots or holes. Likewise, bad cooling can leave stress in the metal. So, exact heat control is needed for strong parts and right sizes.

What is Air Source Heat Pumps

Air source heat pumps (ASHPs) are smart systems that grab heat from outside air. They move it indoors for warming. They work like air conditioners but in reverse. They can heat or cool based on setup. ASHPs are known for saving energy, low running costs, and being kind to the planet.

Integration of Energy-Efficient Air Source Heat Pumps into Foundry Operations

Compatibility with Existing Foundry Infrastructure

Modern ASHPs fit easily into foundry setups without big changes. Their flexible design lets them work alone or join central heat systems.

Retrofitting Considerations and System Design

Adding ASHPs to foundries means checking space, air ducts, and power needs. For example, the air drying equipment, called the “porter of nature,” turns air heat into hot air for drying rooms. This setup causes little hassle while boosting heat efficiency.

Automation and Smart Control Capabilities

Top ASHPs have clever control screens for real-time checks. Equipped with a visual LCD controller, the operation status, fault information, and process parameters of the drying room are clear at a glance. An IoT remote module lets users manage and track drying room work from a phone app.

Benefits of Using the Most Efficient Air Source Heat Pump in Lost Foam Casting

Enhanced Process Stability and Precision

Maintaining Optimal Mold Temperatures

Keeping mold heat steady helps foam shapes burn evenly without warping. The temperature can be adjusted freely between 35-60 ℃, with a room temperature difference less than 5 ℃. This supports exact control over mold conditions.

Reduction in Operational Energy Consumption

Lowering Fuel Dependency in Heating Systems

Old steam or electric heaters use lots of energy. In contrast, this equipment is efficient, energy-saving, environmentally friendly, and zero emission. It’s a great pick for green foundry work.

Improved COP (Coefficient of Performance) Ratios

The air source heat pump dryer uses a top-notch open-loop and closed-loop design. It has a three-layer heat recovery mode. During dehumidification, the residual heat recovery rate is over 70%. The COP is above 2.0, showing better energy use than old systems.

Environmental and Economic Advantages

Energy-saving ASHPs help the planet by cutting gas emissions from burning fuel. They achieve zero emissions while using less energy. They also save money on bills and boost work reliability.

Factors to Consider When Selecting an Energy-Efficient Air Source Heat Pump for Casting Applications

Evaluating Seasonal Performance Efficiency Ratings (SPER)

SPER shows how well an ASHP works in different seasons. A higher SPER means better efficiency all year. This is key in foundries with changing outside temperatures.

Durability and Maintenance Requirements in Industrial Settings

Industrial ASHPs must handle tough settings with dust, dampness, and constant use. Systems from Hangzhou Ouchen Technology Co., Ltd., have strong builds for long use with little upkeep.

Integration with Renewable Energy Sources

ASHPs work with green energy like solar panels or wind turbines. This cuts carbon use even more and uses clean power for foundry work.

Future Trends in Thermal Optimization for Metal Casting Processes

Future systems will use AI to spot problems early and improve work. Linking with Industry 4.0 tech will let casting machines and heat systems talk smoothly for fully automatic setups.

Choose Hangzhou Ouchen Technology Co., LTD for Most Efficient Air Source Heat Pump

Hangzhou Ouchen Technology Co., Ltd., offers special ASHP solutions for lost foam casting:

Rear Mounted Air Dryer

This rear mounted air dryer machine doesn’t take up drying room space. A bigger water removal device gives stronger dehumidification with the same compressor. These features keep work going with great moisture control.

Indoor Air Dryer

This indoor air dryer device mixes heat pump air energy, condensation, and heat recovery tech. It has three jobs: heating, dehumidifying, and draining with waste heat recovery. It gives custom climate control for drying rooms based on customer needs.

Top Mounted Air Dryer

The company’s lost foam casting top mounted air dryer energy host uses the most efficient air source heat pump. It fixes high energy use, low efficiency, and poor quality of old steam drying. These upgrades make it perfect for modern, green foundries.

FAQ

Q1: What makes an air source heat pump suitable for lost foam casting?

High-precision temperature control makes ASHPs great for keeping ideal mold conditions in lost foam casting.

Q2: Are these systems environmentally friendly?

Yes. They ensure zero emissions during drying, supporting green production goals.

Q3: Can an existing foundry setup be retrofitted?

Absolutely. Hangzhou Ouchen’s modular designs allow easy retrofitting without big changes.

Q4: How to monitor system performance remotely?

IoT modules give real-time updates via phone apps, perfect for smart factory setups.

Q5: Is customization available?

Yes. Solutions are tailored for temperature, humidity, and air flow based on actual needs, ensuring systems meet specific work demands.