The Fundamentals of Lost Foam Casting Technology

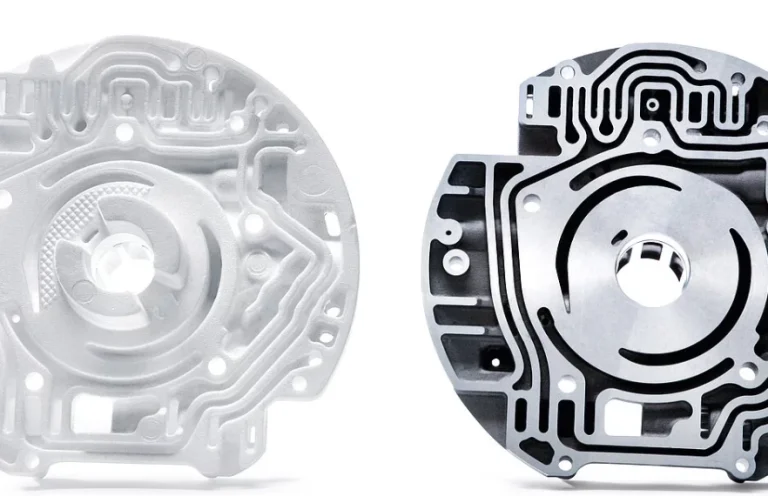

Lost foam casting (EPC ) technology is revolutionizing the manufacturing industry by enabling the production of intricate metal components with exceptional precision. At its core, lost foam casting uses a foam pattern that vaporizes during the casting process, allowing for highly detailed designs that traditional methods struggle to achieve.

According to the American Foundry Society, lost foam casting achieves tolerances of approximately ±0.5mm, significantly enhancing the quality and accuracy of cast parts. Moreover, lost foam casting reduces material waste by up to 15% compared to conventional sand casting methods.

The process begins with the creation of a foam pattern, which is coated in a refractory material and placed within a sand mold. When molten metal is poured into the mold, the foam pattern evaporates, leaving behind a precise metal replica. This streamlined approach eliminates the need for complex tooling setups and shortens production timelines. With advancements in lost foam casting technology, industries such as automotive, aerospace, and industrial machinery are increasingly adopting this method. Market projections indicate that lost foam casting could grow to $3.8 billion by 2025.

Key Advantages of Lost Foam Casting for Manufacturers

Lost foam casting production line has many benefits. It’s a top choice for makers worldwide. One big plus is making complex shapes. These need little extra work to finish. This saves time. It also lowers making costs. No extra steps are needed. The foam shapes turn to gas during casting. This leaves no waste. It helps the environment and saves money.

Another benefit is working with many metals. Lost foam casting uses different alloys. Makers can create light but strong parts. These fit specific needs. This is very useful in cars and planes. Performance and lighter weight matter there.

Flexibility is a key feature. Changing foam shapes is easy. Makers can quickly meet new market needs or customer wishes. In today’s fast world, this gives companies using lost foam casting an edge. They beat those using old methods.

Comparing Lost Foam Casting with Traditional Casting Methods

Lost foam casting is very different from old methods like sand casting. Sand casting needs many steps. It takes a lot of work to make molds from sand. Lost foam casting makes it simpler. It uses expanded polystyrene shapes. These turn to gas when hot metal touches them. This one-step method saves time and work costs.

For part quality, lost foam casting does better. It allows more detailed designs and finer touches. Sand molds limit shapes because of their structure. But lost foam casting gives smooth surfaces. It also has great size accuracy. Little extra work is needed.

From a green view, lost foam casting is better. Old sand casting makes a lot of waste. It uses non-renewable sand. Lost foam casting cuts waste with recyclable foam shapes. It uses less material. This fits today’s focus on being green.

The Environmental Impact of Lost Foam Casting Processes

Lost foam casting stands out for its green benefits. It’s not just about technical wins. The process uses expanded polystyrene (EPS) shapes. These fully turn to gas when hot metal is poured. This cuts extra work and lowers material waste a lot.

Saving energy is key to making lost foam casting eco-friendly. Many makers use heat recovery systems. These catch waste heat from exhaust. Some recover over 40%. This cuts energy use. It lowers carbon output. It also uses resources better.

Recycling efforts help make lost foam casting green. Reclaimed materials are turned into new items like safety shoes. This follows circular economy ideas. By using these green methods with lost foam casting, makers get better production. They also harm the environment less.

Innovations in Lost Foam Casting Equipment and Machinery

New tools in lost foam casting have improved making abilities across fields. The global metal casting market was worth about $139 billion in 2021. It could reach $221.3 billion by 2027. This shows how important new tech like lost foam casting production line is.

One big improvement is fully automatic pre-foaming machines. These control EPS bead density precisely during early stages. They use computer controls. They store settings for steady quality across work shifts. Also, new hydraulic vertical molding machines boost efficiency. They use automatic processes with touch-screen controls and PLC systems.

Automation is a big part of updating lost foam casting systems. Smart tech allows real-time tracking. It makes data-driven changes. This improves quality control. It cuts the need for handwork. As demand grows for top-quality cast parts in fields like cars or planes, using modern machines keeps makers competitive in global markets.

Real-World Applications of Lost Foam Casting Across Industries

Lost foam casting production line has changed many fields. It offers great accuracy and efficiency. It creates detailed shapes with exact sizes. This makes it a top choice for makers worldwide. In the car field, it’s used to make light parts like engine blocks and brackets. These parts improve fuel use. They also keep strength. This meets the need for green solutions.

In planes, lost foam casting is key for making parts like turbine covers and fuel nozzles. The process ensures clean surfaces and exact shapes. These are vital for performance and safety. Also, it can make complex cooling paths. This boosts engine efficiency. Beyond these, machine makers use lost foam casting for strong parts like frames and covers. The method cuts work time and waste. It supports green goals.

Challenges and Solutions in Implementing Lost Foam Casting

Lost foam casting has many benefits. But setting it up has challenges. One big issue is the high starting cost for special equipment. Upgrading old machines or buying new ones for lost foam casting can be expensive. This is tough for smaller makers. To fix this, companies can look at payment plans. Or they can add the tech step by step.

Another challenge is training workers. They need to learn how to handle foam shapes and work with hot metal. Training programs or working with experts can close this gap. Quality control is also hard. Things like foam density and cooling speeds vary. Advanced tracking tools can watch these in real-time. This ensures steady quality.

Future Trends: The Evolution of Lost Foam Casting Technology

The future of lost foam casting production line looks bright. Automation and smart making will drive big changes. As fields use more automatic systems, lost foam casting will get more efficient. It will also grow bigger. New tools like real-time tracking and data analysis will improve quality control. They will cut handwork.

Also, green practices are becoming part of lost foam casting. Makers are finding ways to recycle foam shapes. They are also saving energy during production. These steps improve work efficiency. They also match global green goals.

Hangzhou Ouchen Technology Co., LTD Lost Foam Casting Production Line

Hangzhou Ouchen Technology Co., Ltd leads in lost foam casting innovation. Their modern lost foam casting production line shows top engineering. Their fully automatic pre-foaming machine gives EPS materials with even density. This ensures perfect conditions for casting. It also cuts waste.

Their hydraulic vertical foam molding machine boosts efficiency. It uses automatic processes with touch-screen controls and PLC systems. This allows fast production without losing quality. Also, their central vacuum system ensures steady cooling during molding. It reduces water content. This improves product strength. Contact Hangzhou Ouchen Technology Co., Ltd today for your lost foam casting production line today.

FAQs on Lost Foam Casting Production Lines

What is lost foam casting production line?

Lost foam casting (EPC) is a making process. It uses expanded polystyrene shapes. These turn to gas when hot metal is poured.

How does lost foam casting differ from traditional casting methods?

Unlike old methods like sand casting with many steps, lost foam casting simplifies things. It uses evaporative polystyrene shapes.

What are the quality advantages of using lost foam casting production line?

Lost foam casting gives better size accuracy. It also has smoother surfaces compared to old techniques.

Is lost foam casting more sustainable than traditional casting methods?

Yes, it cuts waste with recyclable foam shapes. It also uses less material.

In which industries is lost foam casting being utilized?

Fields like cars, planes, and machines use lost foam casting. It’s precise and efficient.