Casting is an ancient practice that’s managed to stick around in our lives for the last 7,000 years. Even after all these centuries, it’s hard to find a replacement for such a varied and customizable method for making products. This enduring process continues to evolve, offering manufacturers a wide array of casting processes tailored to different materials, applications, and production volumes. From small intricate parts to large industrial components, casting remains essential in modern manufacturing.

Common Items in Casting

Regardless of the casting method, there are common factors that will help you navigate the processes below. These include: The Pattern or Master Pattern is a reusable or sacrificial shape of the final part used to form the cavity where the molten metal will pour. Die Tools are reusable metal portions common in processes like die casting. Gates, sprues, and vents are channels where molten metal flows into the cavity. Flash is the excess metal that seeps into the areas where a core, cavity, or die interacts. Net shapes are the outcome of most casting processes due to the metal’s shrink rate and cavity surface.

How Casting Works

Casting is a type of manufacturing process that forms materials into different shapes through hot materials and molds. Each casting process has its own unique steps and details that make it stand out from others, but in general, you’ll find that any type of casting involves the pouring or injecting of molten materials into a mold, which then cools and hardens into a finished product.

14 Different Types of Casting Processes

Sand Casting

Sand might seem fragile and crumbly, but with the right type, it can form quality, single-use molds that allow you to create all kinds of castings. It’s an enticing choice for manufacturers because you can shape alloys with high melting temperatures, like steel, nickel, and titanium. You can use sand casting for all kinds of products at medium to high volumes, such as marine flywheels and engines, barbecue grills, skin fittings for ships, and jewelry.

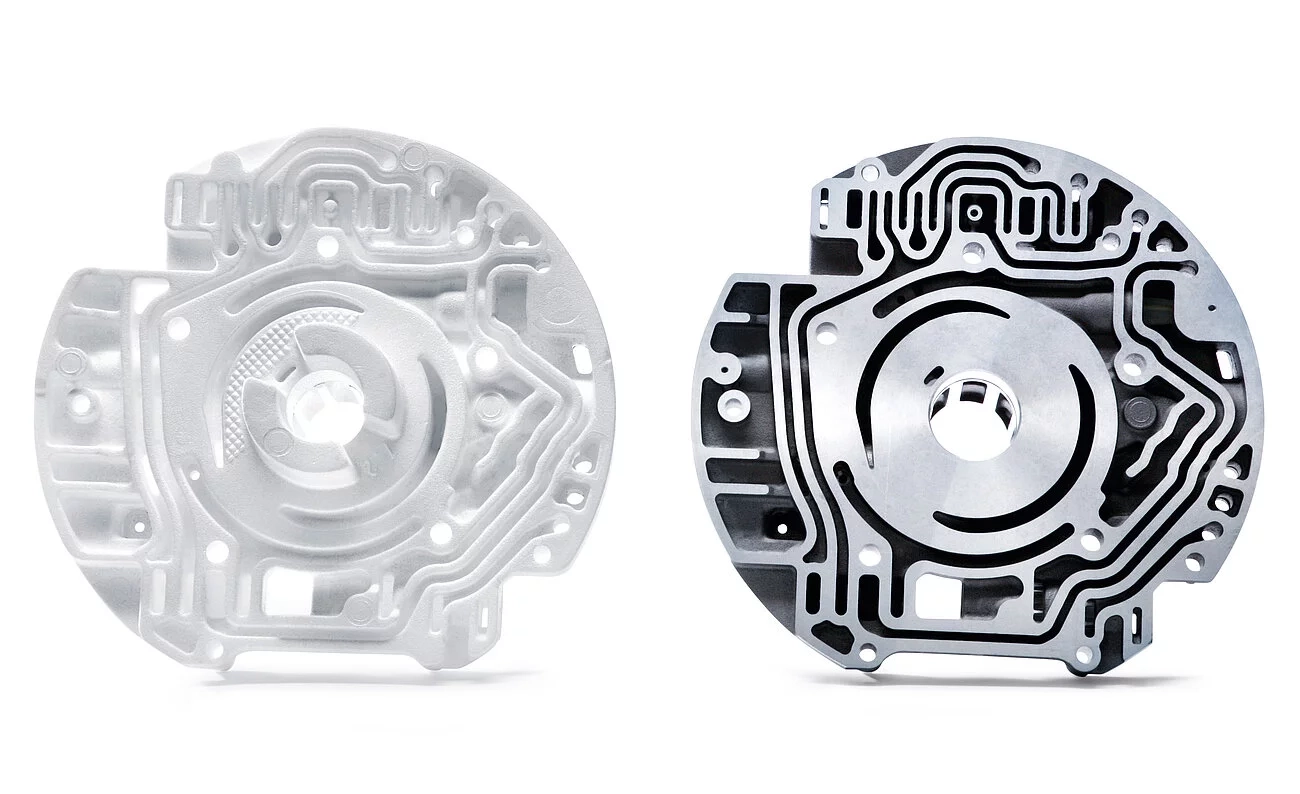

Die Casting (Metal Die Casting)

Once you’ve turned your materials from solids to hot, molten liquids, you can inject them into long-life die-casting molds made of hardened steel. You can implement die casting to make aerospace and automotive components in high quantity production, as well as toys, furniture, and electronics.

Investment Casting

Investment casting works by using wax patterns that are enveloped in ceramic. Afterward, they get pushed into a sand and slurry mix. At this point the wax has done its job and will be evaporated via heat, allowing molten metal to take its place. It is ideal for creating detailed parts like gas turbines or MRI machine components.

Gravity Die Casting

Gravity die casting has you coat a mold’s cavity, pour hot metal in, and wait for gravity to do its job, making it suitable for small parts used in kitchenware or automotive applications.

Continuous Casting

This process gets its name from the steady flow of molten metal you’ll control going in and out of the molds. It produces items like tubes or slabs with high consistency due to rapid cooling.

Shell Molding

Shell molding can give you more accurate dimensions on products, with smoother finishes compared to traditional sand molding. It involves forming a shell around a heated pattern using resin-coated sand.

Lost-Foam Casting

With lost-foam casting, you’ll inject molten metal into a foam mold that’s surrounded with support sand. The polystyrene foam will burn away and gas will disperse through the sand, leaving behind highly detailed shapes.

High Pressure Die Casting

High pressure die casting funnels molten metal quickly into a mold under certain pressure, producing dense parts efficiently. It’s widely used in automotive parts manufacturing.

Centrifugal Casting

This works by rotating a permanent mold and pouring molten material in at the same time. It creates cylindrical shapes like pipes or flywheels.

Permanent Mold Casting

With this method, you’ll use a clamped mold that allows for molten metal to shimmy in and harden. It provides precision for industries like aerospace.

Vacuum Casting

Where you’ll find it differs is where this all takes place—in a vacuum. This environment reduces contamination risks when making prototypes or complex parts.

Low-Pressure Casting

In low-pressure casting you’ll use lower pressures to mold and cool molten metal. It offers strong dimensional accuracy but slower cycle times than high-pressure alternatives.

Squeeze Die Casting

Squeezing, pressing, melting, and forging are a few of the functions that take place in the squeeze die casting process. The result is pore-free components ideal for structural parts.

Plaster Casting

Plaster casting may remind you of Plaster of Paris molds kids use, but at scale it’s used for gears or decorative items using gypsum-based molds.

Materials Used in Casting

It all depends on the type of casting you’re looking to do, but commonly used materials include:

- Metals: iron, aluminum, copper, zinc

- Alloys: bronze and brass

- Ceramics: clay-based materials

- Plastics: thermoplastics molded under heat

- Composites: resins mixed with fibers

- Rubber: flexible molding material

- Glass: artistic or thin-walled applications

- Concrete: architectural elements

The Advantage of Lost Foam Casting

Lost foam casting offers several distinct advantages, making it an attractive option for various manufacturing needs.

One of the key benefits of Lost foam casting is its ability to produce complex shapes with high precision. This method reduces the need for secondary machining since the casting can achieve intricate features and fine details directly. Additionally, it allows for thin-walled parts, which are typically challenging to produce with other methods.

Lost foam casting is also cost-effective due to the reduced need for tooling and the ability to reuse the sand mold. It eliminates the need for core removal, which is common in other casting methods, further reducing labor and material costs. The process is highly adaptable and can be used with a variety of materials, including ferrous and non-ferrous metals.

Unlock the Potential of Your Business with Hangzhou Ouchen’s EPC Equipment

Hangzhou Ouchen Technology Co., Ltd. stands at the forefront as a professional manufacturer specializing in advanced EPS equipment specifically designed for lost foam casting. The company introduces German EPS/EPP top technology combined with a number of independent intellectual property patents, delivering solutions focused on automation efficiency and energy conservation.

For manufacturers seeking reliable partners in scaling up their lost foam operations,

Hangzhou Ouchen provides complete digital solutions—from design consultation through installation—to help businesses achieve low-carbon output with maximum productivity efficiency.