Introduction to Lost Foam Casting and EPS Block Molding Machines

Lost foam casting offers a fresh way in current foundry work. It allows the making of tricky metal parts with good accuracy and little waste. This method uses foam patterns from expanded polystyrene (EPS). Workers coat them, bury them in sand, and then molten metal replaces the foam by turning it into gas. Foundries that use this approach gain from less need for cutting and better surface looks. So, it fits well for fields like cars and planes.

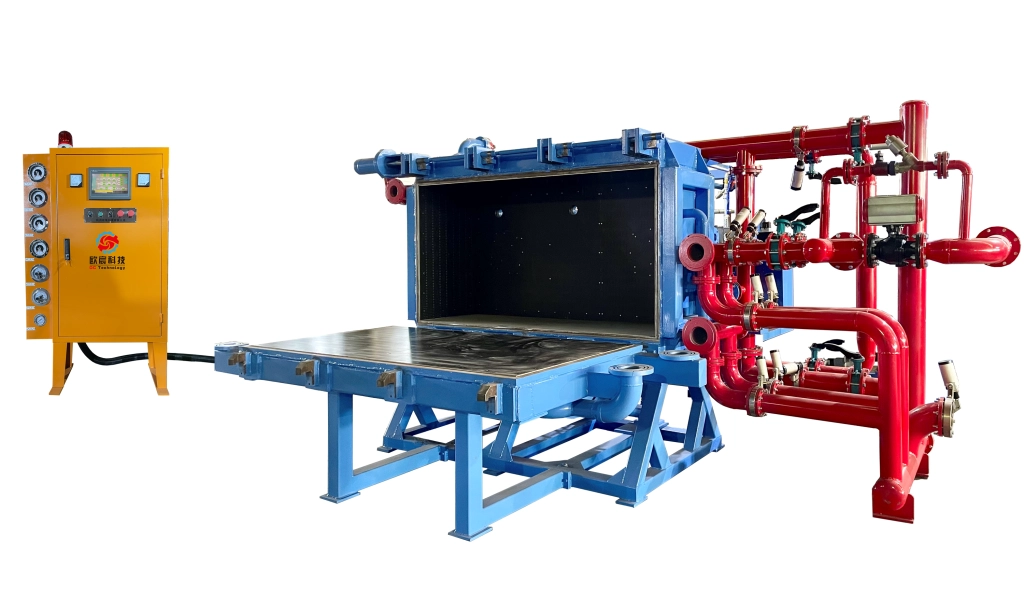

At the core of this method sits the EPS block molding machine. It is a vital tool that shapes the first foam blocks for patterns. EPS block molding machines help make big, even foam sheets or blocks suited to certain casting needs. These machines keep steady density and quality. And that affects the end casting results.

For foundries hunting an EPS block molding machine for sale, choices exist that stress automation, power savings, and strength. Such tools fit smoothly into lost foam casting setups. They boost total output.

Understanding the Lost Foam Casting Process

The lost foam casting process starts with forming EPS patterns. These copy the wanted metal piece. Workers make them with special tools, including EPS block molding machines. The machines expand and shape polystyrene beads into firm blocks. Once shaped, the foam gets cut into forms, covered with a fire-resistant mix, and put in a box full of loose sand. Molten metal poured in burns away the foam. It leaves a sharp space that hardens into the final part.

This way skips old pattern pulling. So, it cuts flaws like split lines, sand gaps, and rough edges. It permits detailed shapes hard with usual sand casting. It gives close fits like in wax casting but at cheaper prices.

EPS block molding machine makers have improved this tech to handle diverse foam weights. Thus, patterns hold up in the casting setting. Compared to sand casting, lost foam casting brings better size truth and green perks, like less stuff waste and power use. Foundries with EPS block molding machines see quicker making rounds. Some setups finish foam board shaping in just 8-10 minutes per round.

Key Features of EPS Block Molding Machines

Modern EPS block molding machines add smart traits to boost work in lost foam casting uses. Control setups often have PLC programmable controllers with touch screens for full auto runs. This leads to few breakdowns and easy upkeep. Extra expert systems allow smart changes to steam amount and heat level. They offer far-off watching through link ports.

Process updates include negative pressure and pulse high-flow cold air cooling. These double speed over old ways. Auto air feeding and vacuum help keep even board density. One-time shaping choices permit no-person loop making.

Unique plans like anti-7-shaped steam drain give even warming for big foam stuff. This betters item stick and hardening. Making speed shines, with fit for co-polymer and EPS materials, fast feeding and cooling rates, and low water in done boards.

Build plans use thick square steel and strong plates for lasting use. Central hydraulic spots ensure safe work. Branded parts add trust.

These traits make EPS block molding machines key for foundries planning to grow lost foam casting work.

Benefits for Foundries in Adopting EPS Block Molding Technology

Foundries adding EPS block molding machines to their lost foam casting lines get big gains. Accuracy in foam pattern making leads to castings with small gaps and smooth faces. This cuts after-work needs and stuff use. So, it means money savings and quicker market time for hard parts.

Power savings is another main plus, as these machines run with low use during making rounds. The skill to change plate sizes without steps via encoder-run rods eases work. It allows custom via touch screen entries. For big runs, the add of reused stuff lifts green ways without hurting quality.

EPS block molding machine factories stress automation to cut labor wants. This lets foundries aim on main casting tasks. In spots like China, where EPS block molding machine making is focused, reach to new models aids world foundries in raising edge.

Overall, these machines lift the speed and quality of lost foam casting. They make a wise buy.

Selecting Reliable EPS Block Molding Machine Manufacturers

When checking EPS block molding machine manufacturers, aim on those with skill in lost foam casting tools. Trusted givers offer machines that blend well with current foundry sets. They feature strong warranties and after-sale help.

China EPS block molding machine suppliers lead in new ideas. They mix world tech with local making strengths to give cheap fixes. Seek makers that favor high-end smart traits, such as hydraulic systems and vacuum molding skills. EPS automatic vacuum shape molding machines, for example, boost accuracy by auto shaping. This cuts human slips and betters flow.

These machines often include vertical or horizontal setups to match diverse making scales. EPS block molding machine factories should show a past in making lasting tools, with parts from trusted suppliers.

For foundries seeking an EPS block molding machine for sale, matching details like round times, power use, and custom choices ensures fit with work needs.

The Role of China in EPS Block Molding Machine Advancements

China acts as a center for EPS block molding machine growth. Dense making zones foster quick tech steps. China EPS block molding machines include German-style plans and own patents. They stress automation and power savings. This sets Chinese makers as main players in giving world foundries tools for lost foam casting.

New ideas from China include smart systems that fit to changing making wants. They back the making of good foam patterns. The aim on low-power, high-speed models matches world green rules. This makes these machines appealing for earth-aware runs.

As need grows, China EPS block molding machine sends keep rising. They offer trusty choices for foundries around the world.

OC Technology

OC Technology serves as a premier manufacturer, supplier, and factory of lost foam casting equipment, delivering high-end solutions tailored for foundries. The lineup includes foam sheet machines for adjustable plate sizing, horizontal forming machines for efficient shaping, indoor and top-mounted air dryers for material preparation, central vacuum systems for clean operations, lift-type paint mixers, maturation silos, rear-mounted air dryers, and vertical PLC hydraulic forming machines. These offerings underscore commitment to quality and innovation in EPS block molding technology.

FAQ

What is lost foam casting?

Lost foam casting is a metal casting process where EPS foam patterns are used to create molds, which evaporate upon contact with molten metal, resulting in precise castings without traditional mold removal.

How does an EPS block molding machine work?

An EPS block molding machine expands polystyrene beads into blocks using steam and pressure, with automated controls for size adjustment and uniform density.

What are the advantages of using EPS block molding machines in foundries?

These machines offer high efficiency, low energy use, precise foam production, and integration with lost foam casting for reduced waste and improved part quality.

Are China EPS block molding machines reliable?

China EPS block molding machines are known for advanced technology, durability, and cost-effectiveness, making them a popular choice for global foundries.

What features should be considered when buying an EPS block molding machine for sale?

Key features include PLC controls, vacuum systems, energy efficiency, customizable sizing, and robust construction for long-term reliability.

Contact Premier EPS Block Molding Machine Manufacturer and Supplier for Foundries

Foundries looking to elevate lost foam casting capabilities can connect with OC Technology, a leading manufacturer, supplier, and factory specializing in intelligent equipment. Reach out via email at zyh@oc-epc.com or telephone at +86 15988479417 to discuss tailored solutions, request quotes, or schedule consultations. Factory visits to Xindeng Town, Fuyang District, Hangzhou City, provide insights into production excellence. Act now to integrate cutting-edge EPS block molding machines and drive operational success.