Lost-foam casting stands out as one of the most creative methods in today’s metal casting field. People also call it evaporative pattern casting (EPC) or the expanded polystyrene process. This method changes a fragile foam pattern into an exact metal part. The pattern simply evaporates when the hot metal pours in. It started in the late 1950s. Workers improved it over many years. Now, lost-foam casting gives great detail. It cuts down waste. It also makes production smoother for tricky shapes.

What Is Lost-Foam Casting?

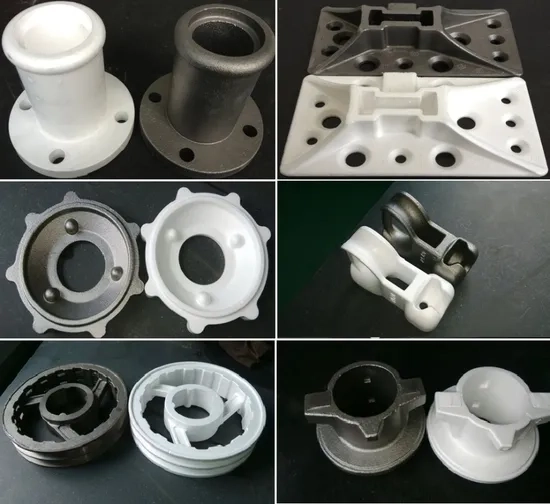

Lost-foam casting uses expanded polystyrene (EPS) foam as a pattern that disappears. The foam copies the exact shape of the final metal piece. Workers coat the foam with a special heat-resistant material. Then they place it in dry sand. Molten metal goes in and turns the foam into gas completely. This way skips old-style cores and parting lines. It allows parts close to the final shape with very little extra work afterward.

The idea came from a 1956 patent by H.F. Shroyer. He put foam patterns in green sand for casting metal. In 1958, people set it up as a standard method. It grew into the full-mold style that many use now.

What Is the Importance of Lost-Foam Casting in Manufacturing?

Lost-foam casting matters a lot for green and smart manufacturing. It uses less energy than regular sand casting. It creates fewer carbon emissions too. Also, it wastes less material and metal. These points help make cleaner factories. They match the world’s push for less harm to the environment. The method creates very accurate parts. This cuts down on machining and lowers total costs when making many items.

How Does Lost-Foam Casting Work?

The lost-foam casting process goes through clear steps:

- Foam Pattern and Gating System Production Workers make patterns from EPS foam. These match the final part’s shape. They add a gating system. It has channels for the molten metal to flow. This system connects to or joins the pattern.

- Bonding Patterns and Runners Foam patterns and gating parts join together into one solid piece. This keeps everything lined up right. It helps avoid mistakes during the cast.

- Application of Refractory Coating The whole piece gets dipped in refractory paint. After it dries, this ceramic layer resists heat. It adds strength. It also separates the foam from the sand around it.

- Placement in Dry Sand Workers put the coated piece inside a molding flask. They fill it with dry sand. Sometimes they use green sand with bentonite clay. That gives extra bend for detailed patterns.

- Vibration for Compaction The flask shakes to pack the sand tight around the pattern. This removes empty spots. It makes sure the support stays even.

- Pouring Molten Metal Hot metal pours into the mold. It turns the foam pattern into vapor. Then it fills the empty space to create the cast part.

- Cooling and Cleaning After the metal hardens, the castings cool down. Then workers clean off leftover sand and coating. The sand goes back for reuse.

This method cuts labor. It lowers waste and energy use. At the same time, it allows very detailed designs.

What Makes Lost-Foam Casting Stand Out Among Other Types of Casting?

Lost-foam casting does well at making complicated shapes. It needs no cores or drafts. It avoids extra material buildup called flash. It reaches better size accuracy too. When you compare it to older ways, it makes production easier. It reduces material waste. It also allows parts very close to final shape. This means less extra machining.

What Type of Sand Is Used in Lost-Foam Casting?

Dry sand works as the main support. It stays stable and packs down easily. Green sand mixes sand with bentonite clay. It gives more flex for detailed patterns. Still, dry sand is the main choice for steady results.

What Metals Are Used in Lost-Foam Casting?

Common materials include:

- Steels and Stainless Steels — Valued for strength and corrosion resistance.

- Aluminum Alloys — Lightweight, conductive, and cost-effective.

- Cast Irons (gray or ductile) — Durable for heavy-duty applications.

- Nickel Alloys — Heat- and corrosion-resistant for demanding environments.

Copper alloys can work but need care. They face issues with gas pickup and flaws. Special risers and venting help prevent problems.

What Are the Applications of Lost-Foam Casting?

Lost-foam casting fits parts that need fine details, thin sections, or inner passages. Common examples are engine blocks, cylinder heads, pump housings, cooling system parts, and strong structural pieces that need accuracy.

What Industries Use Lost-Foam Casting Products?

Automotive, marine, military, agricultural, and general engineering sectors rely on this process for lightweight, high-performance components.

What Is the Quality of Lost-Foam Casting Products?

Products show high size accuracy, smooth surfaces, and fine details. Strength depends on the material chosen, the design, and how well the process runs. Good control gives solid and trustworthy results.

Are Lost-Foam Casting Products Heat Resistant?

Yes. Parts often show good heat resistance. This is true especially for alloys like nickel or stainless steel. They work well in hot settings.

What Are the Advantages of Lost-Foam Casting?

- High dimensional accuracy and smooth finishes.

- Elimination of flash and draft requirements.

- Fewer process steps for simplified manufacturing.

- Reduced waste, energy use, and machining needs.

- Capability for complex geometries and consolidated designs.

What Are the Disadvantages of Lost-Foam Casting?

- Higher initial tooling costs for patterns (especially with dies).

- Foam patterns’ vulnerability to damage or distortion.

- Potential for increased porosity from foam decomposition gases.

Is Lost-Foam Casting Expensive?

Initial setup costs run higher than some other ways. But gains like close tolerances, less machining, and near-final shapes balance the price in medium to high volume production.

Is Lost-Foam Casting the Same as Investment Casting?

No. Investment casting uses wax patterns. Lost-foam casting uses EPS foam. Both give good accuracy. But the different materials set them apart.

Lost-Foam Casting vs. Sand Casting

Lost-Foam Casting vs. Sand Casting

| Aspect | Lost-Foam Casting | Sand Casting |

|---|---|---|

| Process | Foam pattern vaporizes in sand | Compacted sand molds removed after cooling |

| Complexity | Ideal for intricate, complex parts | Better for larger, simpler shapes |

| Surface Finish/Tolerance | Smooth, precise dimensions | Rougher surface, looser tolerances |

| Cost/Tooling | Higher upfront, offset by efficiency | Lower for low-medium volumes |

| Part Size/Weight | Versatile for small to large | Suited for heavy, large components |

Frequently Asked Questions on Lost-Foam Casting

Can Copper Alloys Be Used as Casting Material for Lost-Foam Casting?

Yes, but special measures address gas absorption and defects, including risers for venting.

Are Lost-Foam Casting Products High Quality?

Yes, the process delivers precise, durable components with excellent detail when properly managed.

How Does Lost-Foam Casting Compare to Sand Casting?

It offers superior accuracy, smoother finishes, and no core needs. It works best for complex parts. But sand casting fits simpler shapes and larger amounts more cheaply.

Partner with a Leading Lost Foam Casting Equipment Manufacturer

Foundries seeking to optimize lost-foam casting operations benefit from partnering with specialized equipment providers. Advanced automation, energy-efficient designs, and turnkey solutions enhance productivity, precision, and sustainability in white-area processes.

OC Technology, a national high-tech enterprise and key partner of the China Lost Foam Industry Association, excels as a manufacturer and supplier of high-end intelligent lost foam casting equipment. Located in Hangzhou, China, the company integrates German EPS/EPP technology with proprietary patents to deliver efficient, high-quality solutions focused on automation and low energy consumption.

OC Technology offers fully automatic EPS shape molding machines, pre-expanders, energy-efficient air dryers with heat pump systems, high-performance vacuum casting lines, and complete turnkey production lines for white-zone and yellow-zone projects. These systems support industries worldwide with reliable, innovative equipment tailored for modern foundry needs.

Contact OC Technology today to explore customized lost-foam casting equipment solutions and elevate production capabilities.