What is Lost Foam Casting?

Lost foam casting, also called evaporative-pattern casting, is a smart and efficient way to make metal parts. You create a polystyrene foam model of the part you want. Then, you coat it with a special material and put it in sand. When hot metal is poured in, the foam disappears. The metal takes its place, making a precise and complex part. This method is great for parts with tricky shapes, inner passages, and thin walls. It’s perfect for many industrial uses.

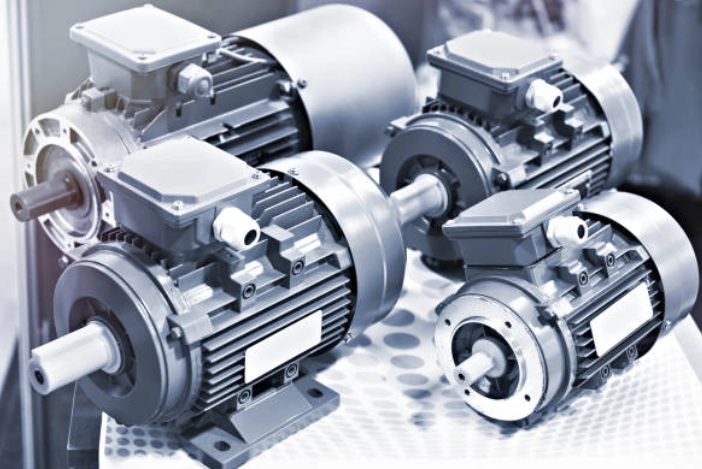

Motor Housing

Motor housings rank first because their simple shape fits well with lost foam casting. This process makes parts with exact sizes and smooth surfaces. It reduces the need for extra work after casting. You can add features like cooling channels or mounting brackets right into the housing. This makes production and assembly easier for electric motors and car parts.

Cylinder Blocks

Cylinder blocks gain a lot from lost foam casting. It avoids problems like big parting lines or uneven walls found in older methods. For blocks with water jackets, a special sand core helps form water passages correctly. The car industry loves this method for its accuracy and low cost in big production runs.

Transmission Cases

Transmission cases are key for vehicle powertrains. Lost foam casting solves issues like tricky core placement. It allows for smaller draft angles, lighter parts, and smoother surfaces. But, parts might bend during casting. Careful foam design and exact pouring temperature control can fix this.

Wear Parts (High Chromium Cast Iron)

High chromium cast iron wear parts, like slurry pump impellers and cone mills, work well with this method. Their simple shapes and ability to handle small flaws lead to high yields at low costs. They’re not great for very large parts due to handling issues. These parts are used in mining, quarrying, and cement industries for their strong wear resistance.

Valve Bodies

Valve bodies, like gate valves and butterfly valves, benefit from lost foam casting’s ability to make even wall thickness without cores. This gives precise sizes with little need for machining. But, you must be careful to avoid leaks during processing. This method’s efficiency makes it a top choice for valve makers.

Pipe Fittings

Pipe fittings, such as flanges, elbows, tees, and socket joints, are made easily with lost foam casting. It creates complex shapes with high accuracy and smooth surfaces. This cuts down on machining needs. Bigger fittings may need extra design steps to avoid bending.

Pump Housings

Pump housings, like those for slurry pumps or double-suction pumps, gain from this method’s ability to make complex inner shapes without traditional cores. This leads to even wall thicknesses that improve performance and reduce waste. For high-pressure uses, careful process control is needed to prevent leaks.

Agricultural Machinery Components

Parts for farm machines, like tractor parts, are great for lost foam casting. It’s cheap and efficient. It meets the need for better surface quality while making strong parts with complex designs. This method is ideal for farm equipment that needs to last in tough conditions.

Machine Tool Components

Lost foam casting removes the need for box molding in big machine tool parts, like lathe beds or milling machine bases. This cuts production costs and allows complex shapes with great accuracy. But, you might need big mold investments at the start.

Metallurgical Machinery Components

Parts like furnace grate bars or anode steel claws for metallurgical machines benefit from lost foam casting’s precision. It forms complex shapes evenly. These parts have great wear resistance, which is key for working in high heat or rough materials.

Choose Hangzhou Ouchen Technology Co., Ltd. for Lost Foam Casting Equipment

Hangzhou Ouchen Technology Co., Ltd., located in Xindeng Town of Hangzhou’s Fuyang District, is a top name in EPS equipment manufacturing. They specialize in smart lost foam casting equipment. The company uses German EPS/EPP technology and holds several unique patents. They focus on automation and high-end equipment making.

Their air energy heat pump drying systems are built for lost foam processes. They save energy with zero-emission operation while keeping drying quality high. Their molding machines have cool features like automatic bead filling, pulse feeding guns for multi-angle injection, and PLC-based controls made for EPC processes. They even have special machines just for motor housing production.

With awards like “Zhejiang Province Science & Technology SMEs,” Hangzhou Ouchen is a leader and trusted partner in China’s lost foam industry.

FAQ

What materials are commonly used in lost foam casting?

Common materials include grey iron, ductile iron, aluminum alloys, carbon steel, stainless steel, low alloy cast iron, and high chromium white cast iron.

What industries benefit most from this process?

Automotive (engine blocks & transmissions), agriculture (tractor parts), metallurgy (furnace parts), valve, and pump manufacturing use this method a lot.

Are there size limitations?

Yes, small-to-medium parts work best. Larger parts may face issues like bending or handling difficulties. Design tweaks can help with some problems.

How does it compare economically?

Lost foam casting saves on tooling costs over time. It needs less machining, especially for large batches of parts with complex shapes.

Why choose Hangzhou Ouchen Technology Co., Ltd.?

Hangzhou Ouchen Technology Co., Ltd offer full solutions—from design to installation—with cutting-edge tech made for the lost foam industry. Their systems are efficient, reliable, green, and deliver top-notch precision.