Expandable Polystyrene (EPS), a light and useful foam material, has a key place in today’s production world. It is especially important in lost foam casting. There, exact foam patterns are needed to make complex metal parts. EPS is famous for keeping heat inside and staying strong. It helps create patterns that disappear completely when hot metal is poured. The result is very accurate castings with almost no flaws. This blog post looks closely at EPS block molding. That is the basic step to make big foam blocks. These blocks are later used in lost foam casting for fields like cars, planes, and big machines.

EPS Building Block

EPS starts as tiny solid beads made of polystyrene resin. A blowing agent like pentane is added inside them. The agent stays quiet until heat wakes it up. In lost foam casting, these beads are very important. They form the patterns that vanish during pouring. When steam touches the beads, the agent makes them grow up to 40 times bigger. This creates the well-known closed-cell foam look. The final material has densities from 10 to 50 kg/m³. Such blocks are strong yet light. People can cut them into detailed shapes easily. The surface stays smooth and sizes stay correct.

The pre-expanded beads join together very well. They lock into each other without gaps during the next steps. For lost foam casting, every bead must grow the same way. If not, empty spots or uneven melting can happen. That might cause holes or sand inside the finished metal part. New ways of putting the agent into beads have made EPS better for busy factories. The results are always the same when making patterns for things like engine blocks or pump bodies.

EPS Block Molding Process

The EPS block molding process turns pre-expanded beads into large, solid foam blocks. It uses careful heat and pressure steps. This way works great for lost foam casting. The blocks become raw material. Workers later cut them with CNC machines into exact patterns. The whole method focuses on speed and steady quality. That meets the strict needs for perfect metal castings.

Pre-Expansion

Pre-expansion is the first big change for raw EPS beads. They become foam ready for molding. Inside special machines called pre-expanders, beads move around in a steam room. The heat reaches 90-110°C and pressure stays around 0.5-1.5 bar. This makes them grow evenly. The time inside is usually 30-120 seconds. Workers set it to reach the wanted density. Too much growth would make the final block weak.

For lost foam casting, even growth matters a lot. It keeps patterns steady later. Modern machines use two or more stages of expansion. This gives better bead sizes and less difference between them. Such careful work makes sure the molded blocks can handle coating and sand without bending.

Mold Design and Materials

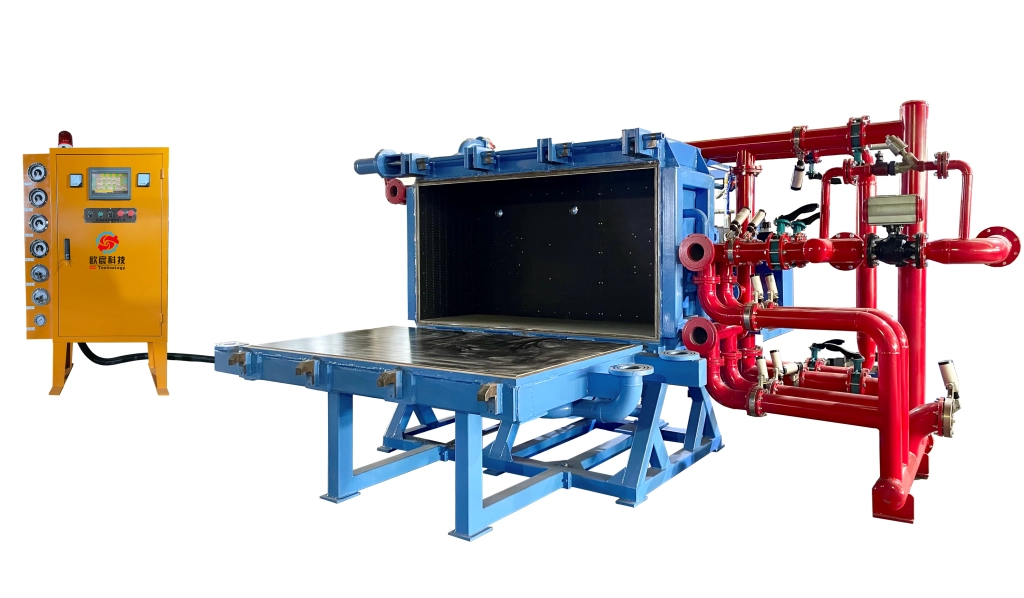

Good mold design is the heart of block molding. It helps heat move fast and beads spread well. Most molds are steel, sometimes mixed with aluminum to be lighter. Walls are 20-50 mm thick. They must stand many steam cycles up to 120°C. Inside, there are filling holes around the edge and vents in the middle. These help beads go everywhere the same.

In lost foam casting work, vents let extra gas out quickly. That stops holes inside that could hurt the pattern when metal is poured. Special coatings like Teflon or ceramic make blocks come out easy. One mold can last over 10,000 cycles. Many molds are built in parts. Users can change them for different block sizes, from 1m x 1m x 0.5m up to 6m x 1.2m x 1m. Big sizes fit large parts perfectly.

Process Parameters and Control

After beads fill the mold, steam goes in for 2-5 minutes at 0.8-1.2 bar. Heat softens the beads just enough. They melt together nicely. Then cooling starts. Water spray or vacuum air does the job. The block becomes hard in 10-20 minutes. Computers called PLC watch everything at once. They change steam with smart valves. Density stays almost the same, with less than 5% difference.

In lost foam casting, exact heat control stops beads from falling apart too soon. The block must stay stronger than 100 kPa. That strength helps when sand is shaken around the pattern. Sensors check pressure and moisture all the time. This makes cycles faster. A factory can make 50-100 blocks each shift. Heat recovery systems save energy too.

Quality Control Measures

When molding finishes, each block gets careful checks. These keep quality high for lost foam casting. People look for bumps or marks on the surface. They measure with calipers. Sizes must stay within ±2 mm. Workers cut small pieces to test density. Good blocks show less than 3% change across the whole piece.

Sound wave tests find hidden problems without cutting. Pressure tests show how much weight the block can hold. Every batch gets a number. Records help find what went wrong if needed. All these steps make sure EPS blocks work the same every time. Scrap becomes very low in the casting steps later.

The Importance of Vacuum Technology (Optional)

Using vacuum in block molding makes things much better. It is very helpful for accurate lost foam casting patterns. Vacuum starts right after steaming. It pulls at -0.4 to -0.6 bar. Air and water come out fast. Cooling becomes 30-50% quicker. Beads stick together even stronger. The surface feels smoother. Water left inside drops below 4%. Cracks almost never happen while blocks wait in storage.

In foundries, vacuum stops heavy and light areas inside the block. Patterns melt the same way when metal over 1,400°C hits them. Newer machines reuse the steam. This saves power and helps the planet. Cycles can finish in less than 15 minutes. That speed is perfect for making many car parts every day.

Applications of EPS Blocks

After cutting, EPS blocks are ready for many lost foam casting jobs. Car factories use them for cylinder heads and transmission cases. Thin walls down to 3 mm are possible. Plane makers build quick test parts for turbine blades. Light blocks help change designs fast.

Building workers use EPS for warm foundation forms. But in casting, the blocks shine when making strong iron fittings. Pumps and valves also come from these blocks. Undercuts form without extra cores. Fewer parts mean simpler work. In the end, EPS blocks save up to 20% compared to old sand casting.

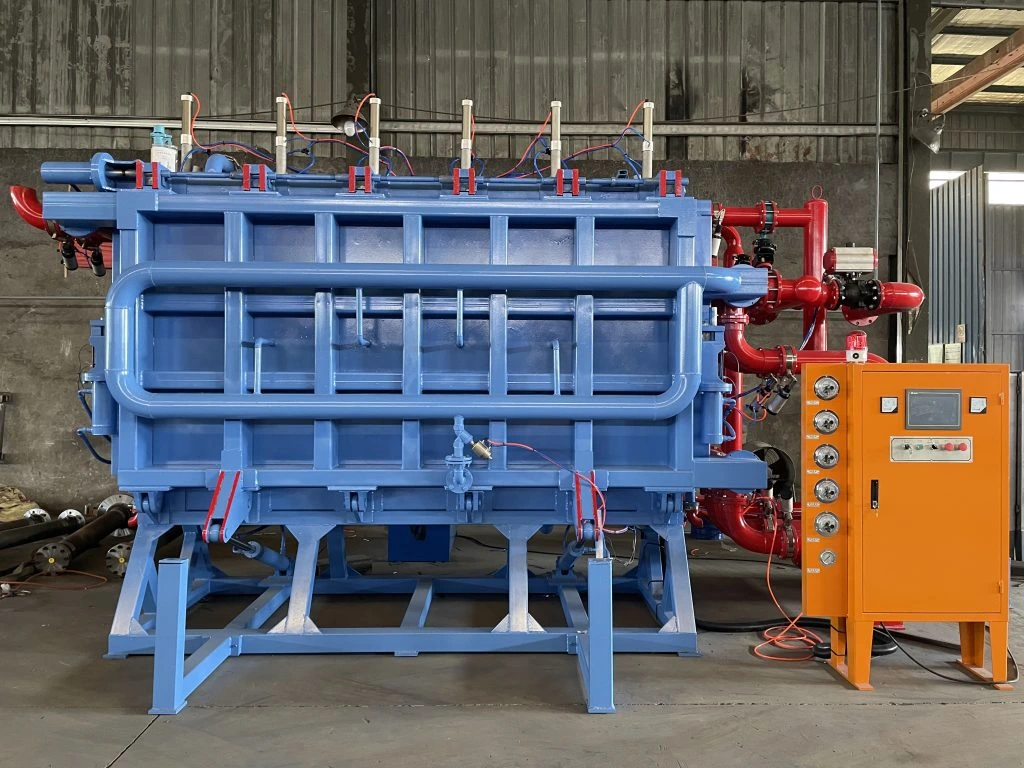

Choosing the Right EPS Block Molding Machine

Picking an EPS block molding machine needs careful thought. It must match what the factory needs for lost foam casting. Machines make 5-50 m³/hour. That decides how many blocks per day. Flexible mold spaces allow different sizes. High automation with servo steam controls gives steady quality every time.

Look for machines that use little power, under 200 kWh per ton. Strong metal fights rust in wet places. Easy links to silos and dryers make the line run smooth from start to finish.

Safety Considerations in EPS Block Molding

Safety is always first when running EPS block molding. Hot steam needs strong covers and safety valves set to 2 bar. Workers wear thick gloves and face protection against burns.

Bead dust needs good filters. Air must stay cleaner than 5 mg/m³. Doors stay locked while the machine works. Strong bases keep heavy units steady. Following ISO 45001 rules keeps everyone safe around casting areas.

Conclusion: The Building Blocks of Innovation

The EPS block molding process supports the accuracy and speed of lost foam casting. It turns simple beads into smart patterns. These patterns change how metal parts are made. Every step, from pre-expansion to final checks, helps create perfect results. New machines and vacuum systems push the field ahead. EPS molding stays the main base for modern, green, and strong production.

FAQ

What is the primary role of EPS blocks in lost foam casting?

EPS blocks provide the raw material for machining evaporative patterns that vaporize during metal pouring, enabling intricate designs without traditional cores.

How does vacuum technology improve EPS block quality for casting applications?

It removes trapped air and moisture, ensuring uniform density and smoother surfaces that enhance pattern stability and reduce casting defects like porosity.

What density range is optimal for EPS blocks used in lost foam casting?

Densities between 15-25 kg/m³ balance machinability and evaporative cleanliness, minimizing residue during high-temperature pours.

Can EPS block molding machines handle recycled materials?

Yes, modern machines incorporate adjustable mixing ratios to integrate up to 30% recycled EPS, promoting sustainability without compromising block integrity.

What are common defects in EPS block molding and how are they prevented?

Voids and uneven fusion are mitigated through precise steam control and venting, with quality checks ensuring compliance for reliable casting performance.

Empower Your Foundry with Premium Lost Foam Casting Equipment from a Trusted Manufacturer and Supplier

Foundries and manufacturers seeking to optimize lost foam casting production lines turn to specialized suppliers for reliable, high-efficiency equipment. As a leading manufacturer, supplier, and factory of advanced lost foam casting solutions, OC Technology delivers turnkey systems that integrate seamlessly into existing workflows. Explore our range, including fully automatic EPS shape molding machines for precise foam pattern production, energy-efficient foam sheet machines compatible with EPS and co-polymer materials, horizontal and vertical PLC hydraulic forming machines for versatile block creation, maturation silos for bead storage, indoor and top-mounted air dryers with heat pump technology, central vacuum systems for defect-free pouring, and lift-type paint mixers for uniform coatings. Contact OC Technology today at +86 15988479417 or zyh@oc-epc.com to request a customized quote and elevate your casting efficiency with proven, innovative machinery.