Introduction to Lost Foam Casting

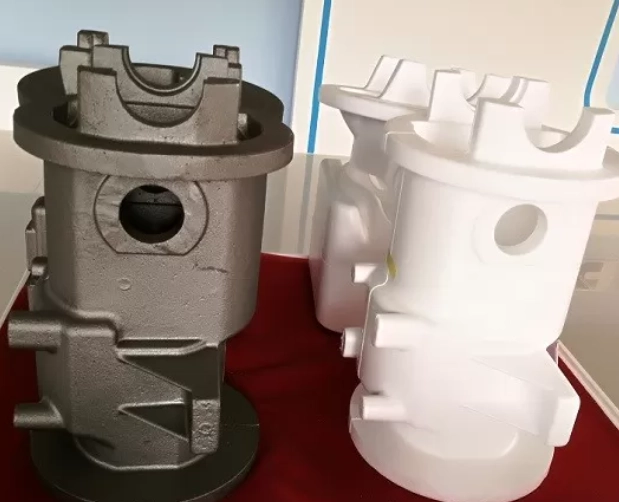

Lost foam casting is a new way to shape metal. It uses a foam model to make detailed and exact metal pieces. The foam shape is covered with a heat-proof coating. Then, it’s placed in a sand mold. When hot metal is poured in, the foam melts away. This method gives great accuracy. It needs less finishing work. It can create complex designs.

A big plus of lost foam casting is its use with many metals and blends. This makes it perfect for various fields. But picking the right material for lost foam casting products is key. Different metals have unique strengths, melting points, and flow traits. These affect the final piece’s quality. Choosing the best material ensures the casting is sturdy, precise, and fit for its purpose.

Why Material Selection Matters in Lost Foam Casting

The metal or blend you pick for lost foam casting impacts the piece’s strength, toughness, and performance. Some metals melt and pour easily. Others are great for resisting heat or wear. For example, lost foam casting aluminum flows well into detailed molds. Meanwhile, lost foam cast iron offers strength for machine parts.

Metals act differently when cooling and hardening. They shrink as they cool. If this isn’t handled well, it can cause cracks or flaws. Some metals flow smoothly and fill the foam mold easily. Others need special changes in heat or pouring methods.

Heat traits also matter. A metal that holds heat too long can harm the foam model or cause gas issues. So, knowing how each metal works in lost foam casting helps workers choose smartly.

Key Factors in Choosing Metals for Lost Foam Casting

When picking metals for lost foam casting, think about a few important things. The metal’s melting point sets the furnace needs. It also affects the foam model’s survival during pouring. Metals like alloy steel lost foam casting or lost foam cast iron need more heat control than lost foam casting aluminum.

How well the metal flows is another big factor. Metals with good flow make more detailed shapes. They reduce flaws too. For example, lost foam cast iron and lost foam casting aluminum are known for strong casting results. But they act differently when melted. Cast iron is stronger. Aluminum is lighter and easier for thin shapes.

The metal’s fit with the lost foam casting process is also vital. Some metals work smoothly with the foam and sand mold. Others may need extras like coatings to avoid flaws.

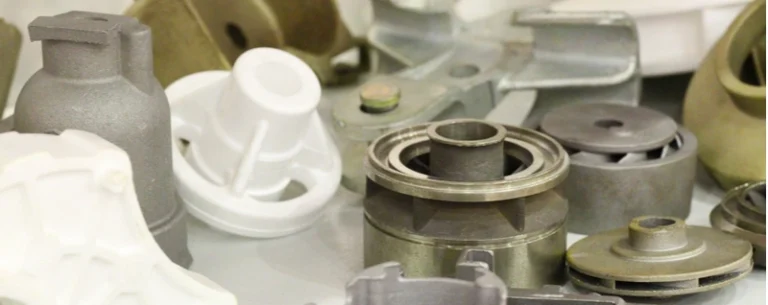

Best Metals and Alloys for Lost Foam Casting

Many metals and blends are popular in lost foam casting. They have special traits. These include aluminum, different types of cast iron, carbon and alloy steel, stainless steel, brass, bronze, and copper. Each has its own benefits, based on the product’s needs.

In the next parts, we’ll look at the strengths and uses of each to help you pick the best for your lost foam casting products.

Aluminum Alloys for Lost Foam Casting

Aluminum blends are top choices for lost foam casting. Blends like ASTM A356, A413, and A360 flow well. They have low weight, resist rust, and pour easily into molds. These are great for making light parts. They’re used a lot in cars and airplanes.

Aluminum lost foam castings make engine parts, gear boxes, and other strong pieces. Reducing weight is key here. Their great heat traits and wear resistance make them a wise pick for precise parts.

Cast Iron: Gray and Ductile Iron

Cast iron is another favorite for lost foam casting. It’s picked when strength and toughness are needed. There are two main types: gray iron lost foam casting and ductile iron lost foam casting.

Gray iron is great at stopping vibrations. It’s used in machine bases and engine blocks. Ductile iron is tougher. It resists impacts well. This makes it perfect for gears, pipes, and suspension parts.

For top performance, the best lost foam cast iron balances hardness, ease of shaping, and wear resistance. It’s great for parts under heavy loads or friction.

Carbon Steel and Alloy Steel

Carbon steel lost foam casting is a strong choice for tough, lasting parts. It can be soft and easy to weld with low carbon. Or it can be hard and wear-resistant with high carbon. AISI 1020 to AISI 1060 are common grades used.

When extra strength or resistance is needed, alloy steel lost foam casting is ideal. Blends like ZG20SiMn or ZG35CrMo have added elements like chromium and molybdenum. These boost wear, heat resistance, and strength. They’re used in tools, machine parts, and pieces for tough settings.

Stainless Steel for Precision Casting

Stainless steel is special for lost foam casting when rust resistance is a big concern. Grades like AISI 304 and AISI 316 don’t rust easily. They’re used in food machines, kitchen tools, and health devices.

Lost foam casting products from stainless steel are clean, strong, and smooth. They’re perfect for clean or high-performance uses. Casting stainless steel is trickier than aluminum or iron. But its benefits are worth the effort.

Brass and Bronze in Lost Foam Casting

For items needing beauty and rust resistance, lost foam brass casting and lost foam bronze casting are great picks. These metals are used in decorative pieces, plumbing parts, and boat equipment.

Brass has a shiny, gold-like look. It’s chosen for hardware and decorations. Bronze is tougher. It’s used in ship parts, bushings, and factory uses. Both metals cast well and give smooth finishes. They’re ideal for detailed lost foam casting products.

Copper-Based Alloys

Lost foam casting copper is used when high electric or heat flow is needed. Copper is perfect for parts in electric cars, power systems, and gadgets.

Casting copper is harder. It can oxidize and shrink. But with the right process and mold design, it makes reliable parts. Its high melting point needs careful heat control during casting.

Equipment and Customization for Optimal Lost Foam Casting

Top-quality tools make a big difference in lost foam casting results. Companies like Hangzhou Ochen Technology Co., Ltd offer full equipment solutions. Their machines include foam-making tools, molding systems, vacuum setups, air dryers, and paint mixers. They also have foam sheet machines and storage silos.

They provide full lost foam casting equipment services. Need one machine or a whole production line? Contact them at +86 15988479417, email zyh@oc-epc.com, or visit https://www.oc-epc.com/.

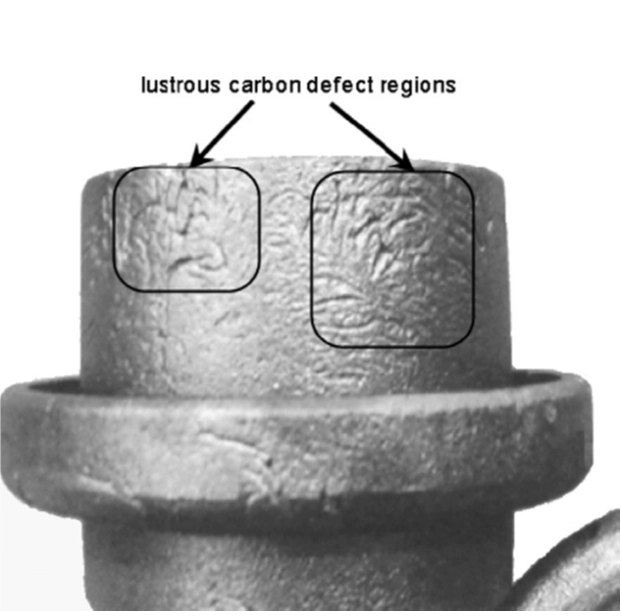

Desafios e soluções no elenco de espuma perdida

Lost foam casting is very helpful. But it has some challenges. One issue is foam models breaking down during pouring. Better foam quality and coatings can fix this. Gas flaws and shrinkage happen too if the process isn’t controlled well.

To avoid these, workers must adjust pouring heat. They should use proper vents and dry molds well. With the right methods, even tough metals like alloy steel lost foam casting or lost foam casting copper can work well.

Applications of Lost Foam Casting Products

Lost foam casting is used in many fields today. In cars, it makes engine blocks, gear cases, and suspension parts. Airplane companies use it for light aluminum lost foam castings. In farming, it creates tools and machine parts from ductile iron lost foam casting or carbon steel lost foam casting.

In art and building design, lost foam casting copper, lost foam bronze casting, and lost foam brass casting make statues and detailed decorations. The wide choice of materials means lost foam casting products can meet almost any design or performance need.

Conclusão

Picking the right metal or blend is the key to success in lost foam casting. Whether you use aluminum lost foam castings, carbon steel lost foam casting, or lost foam brass casting, knowing each material’s strengths helps you get top results.

Ready to boost your production? Hangzhou Ochen Technology Co., Ltd offers great equipment and customization services. Reach them at +86 15988479417, email zyh@oc-epc.com, or visit https://www.oc-epc.com/ for expert help on your next lost foam casting products project.