การหล่อโฟมที่หายไปคืออะไร

การหล่อโฟมที่หายไป เป็นวิธีการที่สร้างสรรค์และปรับได้ มันใช้รูปร่างโฟมโพลีสไตรีนขยายแบบทิ้ง (EPS) เพื่อสร้างชิ้นส่วนโลหะรายละเอียด สําหรับแต่ละชิ้นส่วนที่ทำ รูปร่างโฟม EPS จะเผาไหม้ไป กระบวนการนี้สร้างชิ้นส่วนที่ซับซ้อนและแม่นยำ มันต้องทำงานเพิ่มเติมเล็กน้อยเพื่อที่จะเสร็จสิ้น มันกลายเป็นที่นิยมมากขึ้นสำหรับการทำหล่อเหล็ก มันให้ผลลัพธ์ที่ดี ประหยัดวัสดุ และทำให้การผลิตง่ายขึ้น

กระบวนการหล่อโฟมสูญหาย

การสร้างเครื่องมือโฟม

ขั้นตอนแรกคือการสร้างเครื่องมือโฟม เครื่องมือนี้สร้างรูปร่างโฟม EPS การออกแบบสามารถมีการตัดลึกหรือคุณสมบัติพิเศษเพิ่มไปยังเครื่องมือ ชิ้นโฟมหลายชิ้นสามารถติดกันได้ นี่ทำให้การออกแบบที่ซับซ้อนเป็นไปได้ ความยืดหยุ่นนี้ไม่เป็นเรื่องทั่วไปในวิธีการอื่น ๆ จากนั้นระบบเทจะถูกเพิ่มเพื่อช่วยในการเติม

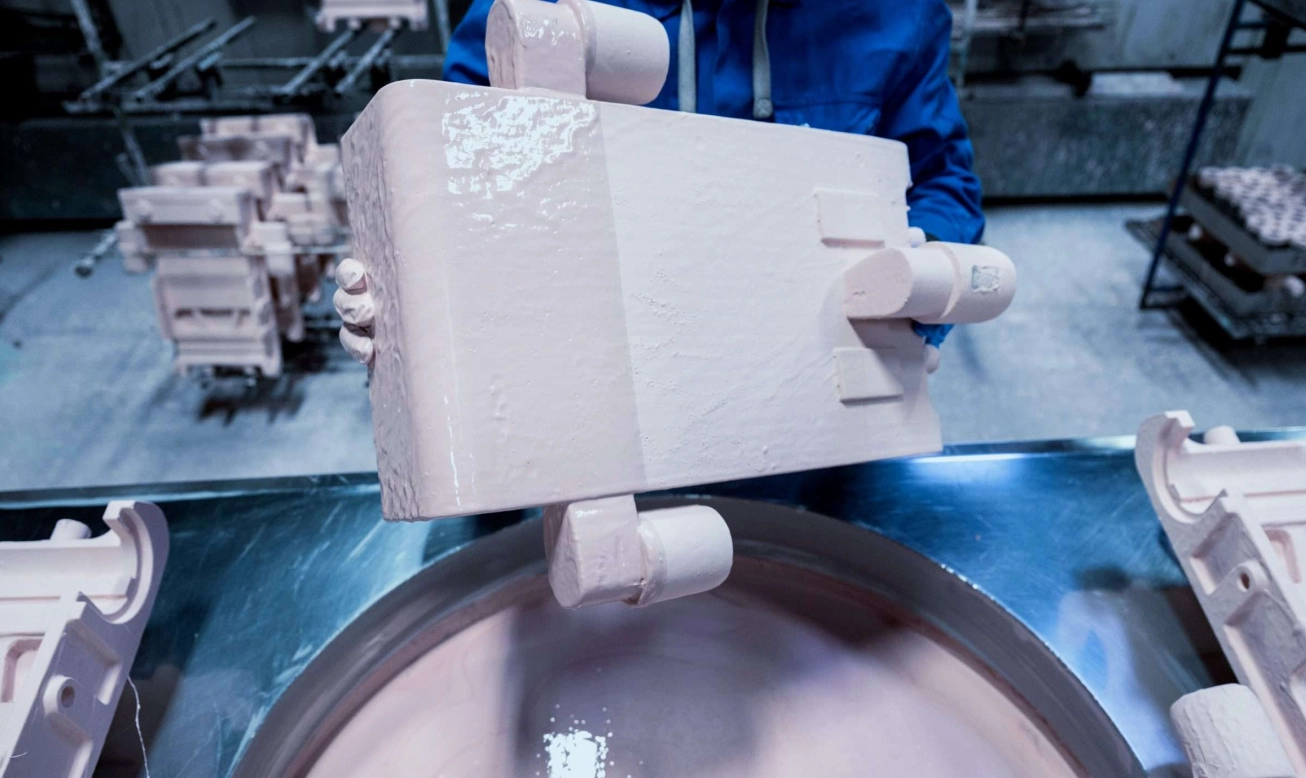

การเคลือบและเครื่องมือแห้ง

หลังจากที่ทำรูปร่างโฟม มันจะได้รับการเคลือบพิเศษ ชั้นนี้ใช้ล้างทนความร้อน มันหยุดทรายจากการผสมกับโลหะร้อน มันยังทำให้พื้นผิวของส่วนสุดท้ายสะอาด รูปร่างที่เคลือบแห้งอย่างสมบูรณ์ นี้ขจัดน้ำใด ๆ ที่อาจทําให้เกิดข้อบกพร่องเมื่อเท

การปั้นทรายและการบรรจุ

รูปร่างโฟมที่เคลือบถูกวางในภาชนะใหญ่ที่มีทรายแห้งและหลวม การสั่นสะเทือนใช้ในการบรรจุทรายรอบรูปร่างอย่างแน่น การสั่นสะเทือนนี้เติมจุดที่เข้าถึงได้ยาก ทำให้รูปร่างมั่นคงในระหว่างเท ทรายบรรจุยึดรูปร่างของแม่พิมพ์เมื่อโฟมเปลี่ยนเป็นแก๊ส

เทโลหะร้อนและระบายความร้อน

เหล็กร้อนจะเทลงในภาชนะที่มีแม่พิมพ์ทรายและรูปร่างโฟม เมื่อโลหะร้อนสัมผัสโฟม มันจะเผาไหม้ไปทันที เหล็กได้รับตำแหน่งของมัน หลังจากที่มันเย็นและแข็ง หล่อเหล็กจะถูกนำออก มันถูกตัดออกจากระบบเทและทำความสะอาดเพื่อใช้

ข้อดีของการใช้โฟมหล่อสูญหายสำหรับหล่อเหล็ก

การหล่อโฟมที่หายไปมีประโยชน์มากมายเมื่อเทียบกับวิธีเก่าเช่นการหล่อทราย:

- รูปร่างที่ซับซ้อนวิธีนี้ช่วยให้การออกแบบรายละเอียด มันมีข้อจำกัดไม่กี่ในการตัดหรือมุม

- ขนาดที่แม่นยำ: ชิ้นส่วนที่ทำต้องทำงานเพิ่มเติมเล็กน้อย พวกเขามีการวัดที่แม่นยำ

- พื้นผิวเรียบกระบวนการให้พื้นผิวที่สะอาดกว่าการหล่อทราย

- ขยะน้อยลง: มันตัดขยะโดยหลีกเลี่ยงเส้นและแกนเพิ่มเติม

- ประหยัดเงินสำหรับชิ้นส่วนที่ซับซ้อน: สำหรับหล่อเหล็กแฟนซี พวกเขาประหยัดเงิน แม้ว่าจะมีค่าใช้จ่ายเครื่องมือสูงขึ้น

- การใช้งานที่ยืดหยุ่น: มันทำงานสำหรับหลายขนาดและรูปร่างของหล่อเหล็ก

ความท้าทายในการหล่อโฟมสูญหาย

ปัญหาที่พบบ่อยระหว่างทำ

การหล่อโฟมที่หายไปมีปัญหาบางอย่าง:

- ข้อบกพร่องรูปร่าง: ความผิดพลาดในการทำรูปร่างโฟมอาจทําให้เกิดปัญหาในส่วนสุดท้าย

- ปัญหาการเคลือบ: การเคลือบที่ไม่ดีหรือการอบแห้งที่ไม่ดีอาจทําให้เกิดเครื่องหมายพื้นผิวหรือบิตที่ติดอยู่

- ข้อผิดพลาดในการบรรจุทราย: บรรจุทรายที่ไม่สม่ำเสมอสามารถทำให้ชิ้นส่วนไม่สม่ำเสมอหรืออ่อนแอ

- ปัญหาการเผาไหม้โฟม: ถ้าโฟมไม่เผาไหม้อย่างเต็มที่มันสามารถทิ้งบิตในแม่พิมพ์

แก้ไขข้อบกพร่องในชิ้นส่วน

เพื่อลดปัญหาเหล่านี้:

- ใช้วัสดุ EPS คุณภาพสูง นี่ทำให้รูปร่างสม่ำเสมอ

- การเคลือบแห้งดีเพื่อหลีกเลี่ยงข้อบกพร่องที่เกี่ยวข้องกับน้ำ

- ใช้เครื่องมือการสั่นสะเทือนที่ทันสมัยสําหรับการบรรจุทราย

- ควบคุมความร้อนและการเทความเร็ว นี่จะทำให้โฟมทั้งหมดกลายเป็นแก๊ส

การหล่อโฟมที่หายไปกําลังเปลี่ยนวิธีการที่เราทำหล่อเหล็ก มันทำให้ผู้ผลิตสามารถสร้างชิ้นส่วนรายละเอียดได้อย่างรวดเร็ว มันรักษาคุณภาพสูง การผสมผสานของความแม่นยํา ความยืดหยุ่น และการประหยัดค่าใช้จ่าย ทําให้มันเป็นทางเลือกที่ดีที่สุด มันใช้ในสาขาเช่นรถยนต์, การเกษตร, และเครื่องจักร.

การใช้งานของการหล่อโฟมที่หายไปในหล่อเหล็ก

การหล่อโฟมที่สูญหายได้เปลี่ยนวิธีการที่เราทำหล่อเหล็ก มันสร้างชิ้นส่วนที่ละเอียดและแม่นยำ วิธีนี้ดีสำหรับการทำชิ้นส่วนผนังบาง มันยังทำชิ้นส่วนที่มีรูปร่างที่ซับซ้อน เหล่านี้ยากที่จะทำด้วยการหล่อทรายปกติ การใช้งานที่พบบางอย่างรวมถึง:

- อุตสาหกรรมรถยนต์: การหล่อโฟมที่หายไปใช้กันอย่างแพร่หลายในรถยนต์ มันสร้างชิ้นส่วนเช่น ซับกระบอกเครื่องยนต์ และตัวเก็บไอเสีย มันยังทำส่วนสำคัญอื่น ๆ ความสามารถในการผลิตชิ้นส่วนที่เบา แต่แข็งแกร่ง ช่วยให้รถยนต์ใช้น้ำมันน้อยลงและทํางานได้ดีขึ้น

- เครื่องมือการเกษตร: ชิ้นส่วนเช่นใบลูก, วงเล็บ, และฝาครอบสําหรับเครื่องจักรฟาร์มมักจะทำในวิธีนี้ กระบวนการทําให้ชิ้นส่วนมีความแข็งแรงและแม่นยำ นี่เป็นสิ่งสำคัญสําหรับการใช้งานหนัก

- วาล์วและชิ้นส่วนปั๊ม: การหล่อโฟมที่หายไปใช้ในการทำร่างกายวาล์วและปั๊มครอบคลุม มันยังใช้สำหรับส่วนจัดการของเหลวอื่น ๆ มันบรรลุการพอดีแน่นและพื้นผิวเรียบ

- เครื่องจักรโรงงาน: กระบวนการทำชิ้นส่วนสำหรับอุปกรณ์โรงงาน เหล่านี้รวมถึงเกียร์ ข้อต่อ และฐานเครื่อง ความสามารถในการสร้างรูปร่างที่ซับซ้อน ด้วยงานเพิ่มเติมเล็กน้อย ทําให้มันเป็นตัวเลือกที่ฉลาด

- อุตสาหกรรมก่อสร้าง: ชิ้นส่วนโครงสร้างเช่น วงเล็บ, ตัวเชื่อมต่อ, และรองรับทําด้วยการหล่อโฟมที่สูญหาย มันแข็งแรงและแม่นยำ

ความยืดหยุ่นของการหล่อโฟมที่สูญเสียช่วยให้ผู้ผลิตผลิตหล่อเหล็กหลายชนิด มันรักษาคุณภาพสูง

ทำงานกับ Hangzhou Ouchen Technology Co., LTD

Hangzhou Ouchen Technology Co. , Ltd มุ่งเน้นการทำอุปกรณ์หล่อโฟมที่สูญหายไปอย่างสมาร์ท บริษัทใช้เทคโนโลยี EPS/EPP ที่ดีที่สุดในเยอรมัน มันยังมีสิทธิบัตรของตัวเองมากมาย มันทำงานบนอัตโนมัติและอุปกรณ์ระดับสูงสุดสําหรับการหล่อโฟมที่หายไป เครื่องมือที่ทันสมัยของพวกเขาควบคุมทุกขั้นตอนของกระบวนการอย่างแม่นยำ

คุณสมบัติหลักของ Hangzhou Ouchen Technology Co., LTD ’ อุปกรณ์:

- ระบบอัตโนมัติเต็มรูปแบบอุปกรณ์ใช้ตัวควบคุม PLC และหน้าจอสัมผัส นี่ทำให้การทำงานราบรื่น

- ประหยัดพลังงาน: มีคุณสมบัติเช่นการปรับเซอร์โวที่ปรับตัวสำหรับไอน้ำและความร้อน นี่ทำให้การใช้พลังงานต่ำ

- การผลิตที่รวดเร็ว: แต่ละบอร์ดโฟมใช้เวลา 8-10 นาทีในการทำ นี่จะให้ผลได้อย่างรวดเร็ว

- การออกแบบที่แข็งแกร่ง: ใช้เหล็กสี่เหลี่ยมหนาและแผ่นเหล็กที่แข็งแกร่ง นี่ทำให้มันแข็งและมั่นคง

- คุณสมบัติที่ปลอดภัย: การเปิดประตูไฮดรอลิกการควบคุมกลางและการป้องกันความดันเกินไปช่วยให้คนงานปลอดภัย

Hangzhou Ouchen Technology Co. , Ltd นอกจากนี้ยังมีเครื่องมือพิเศษ เหล่านี้รวมถึงเครื่องขึ้นรูปไฮดรอลิก PLC แนวตั้งและระบบสูญญากาศกลาง พวกเขายังมีไซโลที่เติบโตและเครื่องผสมสีแบบลิฟท์ เครื่องเหล่านี้ปรับปรุงกระบวนการหล่อโฟมที่หายไป พวกเขาเพิ่มประสิทธิภาพ ตัดขยะ และรับประกันคุณภาพอย่างมั่นคง

ข้อดีของการร่วมมือกับ Hangzhou Ouchen Technology Co., LTD:

- การเข้าถึงเทคโนโลยีที่ทันสมัย

- โซลูชั่นที่กำหนดเองสำหรับความต้องการเฉพาะ

- ความเชี่ยวชาญด้านอัตโนมัติและอุปกรณ์ระดับสูง

- เน้นแนวคิดใหม่และปฏิบัติการประหยัดพลังงาน

การทำงานร่วมกับ Hangzhou Ouchen Technology Co., LTD ช่วยให้ผู้ผลิตปรับปรุงการผลิต มันทำให้ราคาแข่งขัน

คำถามที่พบบ่อย

การหล่อโฟมที่หายไปคืออะไร?

การหล่อโฟมที่สูญหายเป็นกระบวนการ มันใช้รูปร่างโฟมโพลีสไตรีนขยายแบบทิ้ง (EPS) เพื่อสร้างชิ้นส่วนโลหะ สําหรับแต่ละชิ้นส่วนที่ทำ รูปร่างโฟม EPS จะเผาไหม้ไป

หล่อเหล็กประเภทใดที่สามารถผลิตได้โดยใช้วิธีนี้?

การหล่อโฟมที่หายไปสามารถทำให้หล่อเหล็กหลายชนิด เหล่านี้รวมถึงซับกระบอกเครื่องยนต์, ร่างกายวาล์ว, ฝาปั๊ม, เกียร์, วงเล็บ, และชิ้นส่วนโครงสร้าง.

ทำไมเลือกการหล่อโฟมที่หายไปมากกว่าการหล่อทราย?

การหล่อโฟมที่หายไปมีประโยชน์มากกว่าการหล่อทราย:

- ขนาดที่แม่นยำกว่า

- พื้นผิวที่สะอาด

- ความต้องการงานเพิ่มเติมน้อยลง

- ความสามารถในการสร้างรูปร่างที่ซับซ้อน

Hangzhou Ouchen Technology Co., LTD รับประกันคุณภาพในการหล่อโฟมที่หายไปอย่างไร?

Hangzhou Ouchen Technology Co., LTD ใช้อุปกรณ์ที่ทันสมัย มีระบบควบคุม PLC และการปรับเซอร์โวที่ปรับตัว มันยังมีการออกแบบโครงสร้างที่แข็งแกร่ง เหล่านี้รับประกันคุณภาพที่มั่นคงทุกขั้นตอน

Hangzhou Ouchen Technology Co., LTD สามารถปรับแต่งอุปกรณ์ตามความต้องการเฉพาะได้หรือไม่?

ใช่ มีการปรับแต่ง ลูกค้าที่มีความต้องการขนาดที่ไม่ซ้ำกันสามารถได้รับโซลูชั่นที่ปรับแต่งได้

อุตสาหกรรมใดได้รับประโยชน์จากการหล่อโฟมที่หายไป?

อุตสาหกรรมเช่นรถยนต์ การเกษตร อาคาร การจัดการของเหลว (วาล์ว / ปั๊ม) และเครื่องจักรโรงงาน ได้รับผลมากจากวิธีการที่ยืดหยุ่นนี้

การหล่อโฟมที่หายไปกําลังเติบโตในความนิยม มันทำให้การออกแบบรายละเอียดด้วยความแม่นยำมาก มันยังลดขยะ การทำงานกับผู้เชี่ยวชาญเช่น Hangzhou Ouchen Technology Co., LTD ให้การเข้าถึงเทคโนโลยีสูงสุด มันปรับปรุงประสิทธิภาพและคุณภาพของผลิตภัณฑ์