Understanding Lost Foam Casting and Green Sand Casting

การหล่อโฟมที่หายไปคืออะไร?

การหล่อโฟมที่หายไป is a current metal casting method. It uses a foam pattern made of polystyrene. This pattern gets coated with a heat-resistant substance. Then, it is placed in loose sand. When hot metal is poured into the mold, the foam pattern disappears. This leaves a precise metal piece. The method is popular because it makes detailed parts with little extra work.

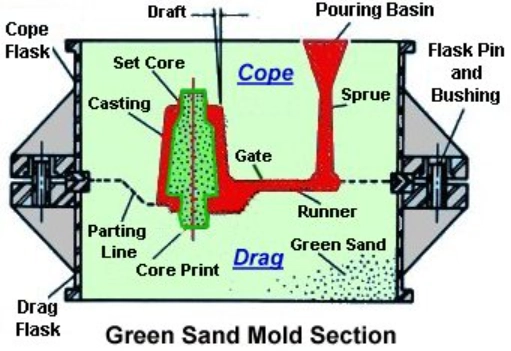

What is Green Sand Casting?

Green Sand Casting is an old-fashioned method. It creates molds from a mix of sand, clay, water, and other items. This mix is pressed around a pattern to shape the mold. After the mold dries, hot metal is poured in to form the part. Green Sand Casting is widely used because it is simple and affordable. It works well for making many basic parts.

Key Differences Between the Two Methods

Green Sand Casting is fairly clean and has less odor. However, it leaves a rougher surface. Lost Foam Casting, on the other hand, provides better accuracy and smoother surfaces. Green Sand Casting can handle large amounts of production well. Yet, it struggles with complicated shapes compared to Lost Foam Casting.

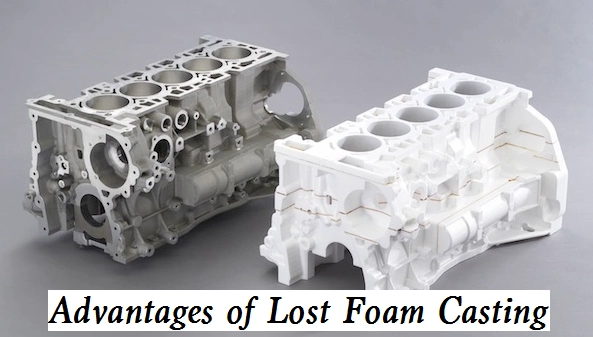

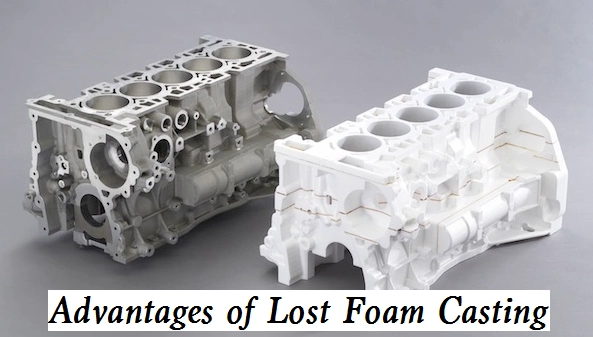

The Advantages of Lost Foam Casting

Superior Precision and Accuracy

How Lost Foam Casting Achieves High Precision

Lost Foam Casting achieves great accuracy. It uses expandable polystyrene patterns. These patterns exactly copy the final part’s shape. Since there are no parting lines, mismatches or misalignments are avoided. These issues are common in other methods.

Benefits for Complex Metal Parts

This method shines in making complex metal parts. It can create detailed designs directly from the foam pattern. No extra machining or assembly is needed. I have noticed less bending in Lost Foam castings. This might be because moisture in sand cools some parts faster than others in other methods.

Enhanced Design Flexibility

Freedom in Creating Intricate Shapes

Lost Foam Casting offers unmatched design freedom. Engineers can create very detailed shapes. These shapes are hard or impossible with Green Sand molds. The process allows new designs for many industries. It supports creative ideas.

Reduced Need for Additional Machining

The high accuracy of Lost Foam castings greatly reduces extra machining needs. Sometimes, no machining is required at all. This saves time. It also lowers costs over time.

Better Surface Finish Quality

Achieving Smooth Finishes with Lost Foam Casting

The foam pattern turns to gas when hot metal is poured. This results in smooth surfaces for cast parts. This quality makes Lost Foam Casting perfect for parts needing good looks or tight measurements.

Comparison to Surface Finish in Green Sand Casting

Green Sand Casting leaves a rougher surface than Lost Foam methods. This often requires extra finishing work. The extra work adds time and cost.

Efficiency and Cost-Effectiveness of Lost Foam Casting

Reduction in Material Wastage

How the Process Minimizes Waste

Lost Foam Casting reduces material waste. It uses exact patterns to ensure metal flows correctly into molds. Also, the loose sand can be reused many times.

Environmental Benefits of Reduced Waste

By cutting down waste and reusing sand, Lost Foam Casting helps the environment. It supports sustainability by using resources wisely.

Lower Production Costs Over Time

Streamlining the Manufacturing Process with Lost Foam Casting

Lost Foam Casting simplifies the process. It reduces labor-heavy steps like mold preparation and extra machining. Over time, these savings add up for manufacturers.

Challenges of Green Sand Casting Compared to Lost Foam Casting

Limitations in Producing Complex Geometries

Green Sand molds struggle with very detailed shapes. They rely on manual shaping. This makes them less suitable for advanced designs needing complex forms.

Higher Post-Casting Processing Requirements

Parts made with Green Sand Casting often need a lot of extra work. This includes grinding or machining to get the right size and surface. These steps increase time and cost.

Potential for Surface Defects and Inconsistencies

The Green Sand mix can vary. This can cause uneven mold quality. As a result, parts may have surface flaws or incorrect sizes. These problems are less common with Lost Foam Casting. Its precise patterns ensure better results.

Applications Where Lost Foam Casting Excels

Industries Benefiting from Precision Components

Lost Foam Casting is known for making highly accurate and detailed parts. It is a top choice for many industries. For example, the car industry uses it for lightweight, complex parts like engine blocks, transmission cases, and suspension pieces. The aerospace industry also uses Lost Foam Casting. It creates high-performance parts needing exact sizes and smooth surfaces.

In the medical field, Lost Foam Casting is key for making surgical tools and implants. Precision is critical here. The method is also used for industrial machine parts. These parts need to be strong and reliable. The energy sector benefits too. Lost Foam Casting helps make parts for turbines and pumps.

Examples of Complex Parts Made Possible by Lost Foam Casting

Lost Foam Casting has unique abilities. It allows the creation of parts with complex shapes. These are hard or impossible with traditional methods. For instance, it can make hollow sections in castings without needing cores or extra assembly. This is great for lightweight structures in cars and planes.

Additionally, Lost Foam Casting combines multiple parts into one. This reduces assembly time and possible weak points. Examples include complex manifolds, detailed brackets, and custom prototypes for specific uses. Aluminum castings made with Lost Foam Casting show high quality with little material waste.

FAQs on the Advantages of Lost Foam Casting

Why is Lost Foam Casting Preferred for Complex Metal Parts?

Lost Foam Casting is chosen for complex parts because of its great accuracy and design freedom. Polystyrene foam patterns ensure every detail is copied exactly. Unlike Green Sand Casting, which uses manual shaping, Lost Foam Casting uses a single-piece mold. This avoids parting lines and mismatches.

I have noticed less bending in Lost Foam castings. This might be due to moisture in sand cooling some parts faster in other methods. This stability makes it ideal for detailed designs without losing strength.

How Does Lost Foam Casting Compare to Green Sand Casting in Terms of Cost?

Green Sand Casting may seem cheaper at first. It has a simpler setup and lower material costs. However, Lost Foam Casting often saves more money over time. It needs less machining and finishing work. This lowers labor costs. Also, Green Sand Casting leaves rougher surfaces. This requires extra steps that add to costs.

Lost Foam Casting reduces waste with precise patterns and reusable sand. These efficiencies lower costs. They also help the environment by using fewer resources.

Learn More About Hangzhou Ouchen Technology Co., LTD’s Lost Foam Casting Equipment

Hangzhou Ouchen Technology Co. , Ltd focuses on top-quality equipment for Lost Foam Casting. They use advanced technology from places like Germany and Japan. Their equipment is highly developed for Lost Foam Casting.

Their products serve many industries. They offer customizable solutions to meet specific needs. Whether you want better accuracy or faster production, Hangzhou Ouchen Technology Co., LTD can help. Their expertise ensures great results with good quality and cost savings.

For companies looking for new casting methods, exploring Hangzhou Ouchen Technology Co. , Ltd’s equipment is a smart move. It opens new possibilities while keeping quality and affordability high.