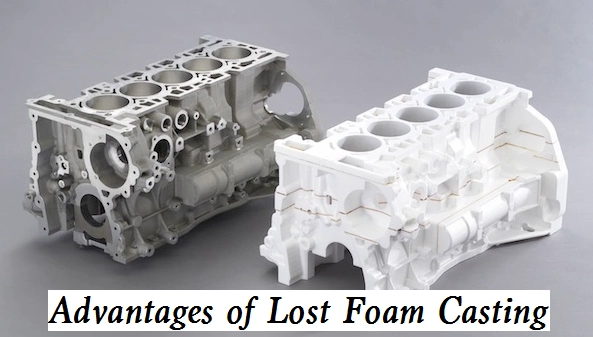

The Role of CNC Machines in Modern Lost Foam Casting

Enhancing Precision in Lost Foam Casting Processes

A cnc machine for lost foam casting factory has changed the industry. It ensures great accuracy in making parts. These machines can handle tricky designs. They keep quality steady across many production runs. By using smart software, a cnc machine for lost foam casting factory reads detailed plans. It makes sure every detail is copied exactly. This accuracy reduces waste of materials. It also improves the final product’s quality.

Automation and Efficiency in Lost Foam Casting Factories

Automation from a cnc machine for lost foam casting factory makes work smoother. It reduces human mistakes. Automated systems need less human effort. This boosts work efficiency. A cnc machine for lost foam casting factory allows constant production with little downtime. This greatly increases output. Also, these machines check and adjust settings instantly. This ensures the best performance during the casting process.

Key Equipment in Hangzhou Ouchen Technology Co., LTD’s Lost Foam Casting System

เครื่อง foaming ล่วงหน้า

The Functionality of Pre-Foaming Machines in the Process

เครื่องจักรล่วงหน้า are critical in preparing raw materials for lost foam casting by expanding polystyrene beads to a desired density. The first generation of domestic pre-foaming machines relied on manual operations, using a measuring cup for raw material input and controlling density based on operator experience. However, this method was prone to inconsistencies due to human error.

How CNC Technology Optimizes Pre-Foaming Operations

Modern pre-foaming machines incorporate PLC computer control systems that automate feeding and foaming processes. This ensures uniform bead expansion and consistent quality. The integration of electromagnetic heating stabilizes barrel temperatures, avoiding issues like “dead beads.” With features like remote debugging and parameter storage, CNC-driven pre-foaming machines enhance operational efficiency and product traceability.

ไซโลสุก

The Importance of Maturation Silos for Raw Material Storage

Maturation silos play a pivotal role in stabilizing expanded beads before they proceed to the next stage. Proper maturation ensures uniform moisture content and density, which are essential for high-quality casting results.

CNC Integration for Efficient Material Handling

CNC technology enhances the functionality of maturation silos by automating material transfer and monitoring conditions within the silo. This level of control prevents inconsistencies during storage and improves overall production quality.

เครื่องปั้นโฟม

Horizontal Forming Machine: Features and Advantages

Horizontal forming machines are designed for efficient foam molding with high-speed operations. These machines ensure uniform pressure distribution during molding, resulting in precise shapes with minimal defects.

Vertical PLC Hydraulic Forming Machine: Precision and Performance

Vertical PLC hydraulic forming machines offer enhanced precision through their programmable logic controllers. They provide greater control over pressure settings, enabling the production of complex geometries with high accuracy.

Central Vacuum Systems

The Role of Central Vacuum Systems in the Forming Stage

Central vacuum systems are integral to the forming stage as they remove excess air from molds, ensuring proper compaction of foam beads. This step is crucial for achieving the desired strength and density in cast components.

CNC-Controlled Vacuum Systems for Improved Heat and Moisture Management

CNC-controlled vacuum systems optimize heat distribution during molding while effectively managing moisture levels. This prevents defects such as warping or uneven surfaces in finished products.

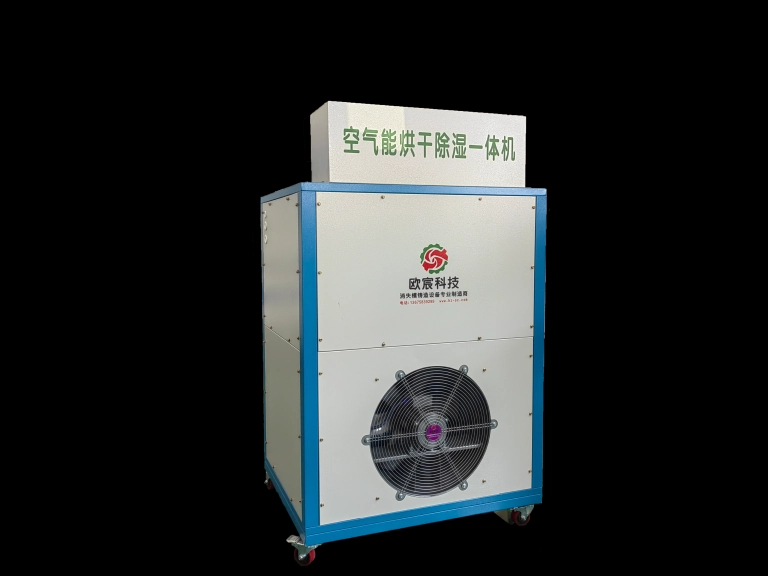

เครื่องเป่าลม

Types of Air Dryers Used in Lost Foam Casting Factories

Top-Mounted Air Dryer: Applications and Benefits

Top-mounted air dryers are compact solutions that save space while providing efficient drying capabilities. They are ideal for factories with limited floor space.

Rear-Mounted Air Dryer: Efficiency and Design Features

Rear-mounted air dryers offer enhanced airflow management, ensuring thorough drying of materials before further processing.

Indoor Air Dryer: Space-Saving Solutions for Factories

Indoor air dryers are designed to fit seamlessly into factory layouts without compromising on drying performance.

ลิฟท์ประเภทมิกเซอร์สี

The Importance of Paint Mixing in the Lost Foam Casting Process

Paint mixing is a vital step in lost foam casting as it prepares coatings that enhance mold surface quality and prevent defects during metal pouring.

CNC-Driven Precision in Paint Mixing Operations

Lift type paint mixers equipped with CNC technology ensure uniform mixing by precisely controlling speed and duration. This results in consistent paint quality that adheres effectively to molds.

เครื่องแผ่นโฟม

Applications of Foam Sheet Machines in Lost Foam Casting Factories

Foam sheet machines produce high-quality sheets used as templates or patterns in lost foam casting processes. These sheets must meet stringent standards for thickness uniformity and strength.

How CNC Enhances the Production Quality of Foam Sheets

Foam sheet machines utilize PLC programmable controllers and touch screen interfaces for fully automated operations. Features like adaptive proportional servo adjustment ensure precise control over steam volume and heating temperature. These advancements result in foam sheets with low water content, high dimensional accuracy, and minimal deformation.

Advantages of Implementing CNC Machines in Lost Foam Casting Factories

Improved Productivity Through Automation

A cnc machine for lost foam casting factory has boosted productivity. It automates many processes. Programmable logic controllers (PLC) ensure smooth operations. They reduce human errors. For example, modern pre-foaming machines use PLC systems. They automate feeding and foaming. This improves efficiency. It also keeps bead expansion and density consistent.

Fully automatic pre-foaming machines have features like one-click start. They also save settings for easy quality tracking. These allow factories to run constantly with little downtime. This greatly increases production rates. Also, electromagnetic heating keeps barrel temperatures steady. It eliminates issues like “dead beads.” This ensures high-quality outputs.

In foam molding, a cnc machine for lost foam casting factory drives horizontal forming machines. They are built for fast operations while staying precise. Vertical PLC hydraulic forming machines also improve productivity. They offer programmable pressure settings. These allow efficient molding of complex shapes. Such technologies speed up production cycles. They reduce time waste.

Enhanced Quality Control Across All Stages

CNC technology ensures quality control in the casting process. It automates key settings like temperature, pressure, and material handling. This reduces variations and flaws in products. For instance, foam sheet machines with PLC controllers control steam volume and heating temperature exactly. This creates foam sheets with low water content. They have even thickness and little warping.

Also, CNC-controlled central vacuum systems manage heat distribution in the forming stage. They handle moisture levels well. This prevents flaws like warping or uneven surfaces. The ability to check and adjust conditions instantly ensures parts meet high standards.

Paint mixing benefits from CNC technology too. Lift type paint mixers with CNC mechanisms mix evenly. They control speed and time precisely. This leads to steady paint formulas. The paint sticks well to molds. This reduces surface flaws during metal pouring.

Cost Savings Through Efficient Resource Utilization

Implementing CNC machines in lost foam casting factories results in significant cost savings by optimizing resource utilization. Automated systems reduce material wastage by ensuring precise measurements and consistent outputs. For instance, quantitative foaming using electronic weighing methods achieves a pre-weight deviation within ±1 gram. This level of accuracy minimizes raw material consumption without compromising on quality.

By integrating cutting-edge CNC technology into various stages of lost foam casting, factories can achieve higher productivity levels, enhanced quality control, and substantial cost savings. These advancements position them as leaders in an increasingly competitive industry landscape.

About Hangzhou Ouchen Technology Co., LTD

Hangzhou Ouchen Technology Co. , Ltd is a leading manufacturer of intelligent lost foam casting equipment based in Hangzhou, China. With German EPS/EPP technology and multiple patented innovations, we focus on automation, efficiency, and high-end customization. Recognized as a National High-Tech Enterprise, we deliver reliable, energy-saving solutions across the lost foam casting process. ติดต่อเราวันนี้ to learn how our CNC-integrated systems can optimize your production