Lost-foam and full-mold casting are super cool types of evaporative-pattern casting. Both use a pattern that zaps away with heat. This nifty trick lets makers create tricky shapes without pulling out the pattern before pouring hot metal. But, even with similarities, these methods differ in how they’re done and used.

The big difference is lost-foam casting uses a foam pattern packed in sand, while full-mold casting doesn’t. Knowing these differences helps makers pick the right method for their needs.

การหล่อโฟมที่หายไปคืออะไร?

Lost-foam casting is a zippy type of evaporative-pattern casting. It uses a foam pattern. The process starts with making a detailed mold from polystyrene foam. Makers craft this foam model and place it inside a sand mold.

Then, hot molten metal gets poured in. The heat makes the foam vanish in a flash, leaving a space that fills with metal to form the final casting. This skips traditional parting lines and cores, giving tons of design freedom. Explore lost-foam at Hangzhou Ouchen.

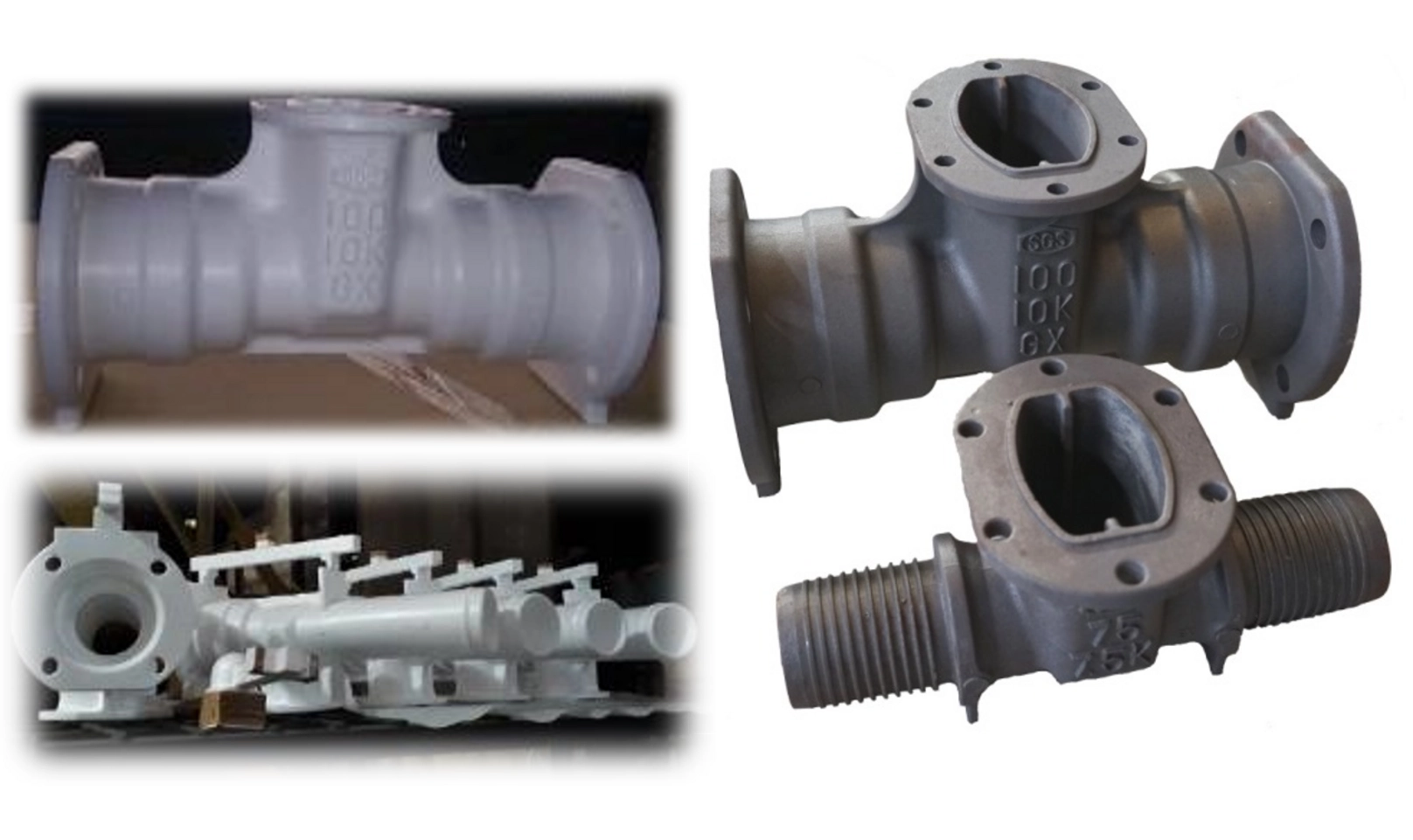

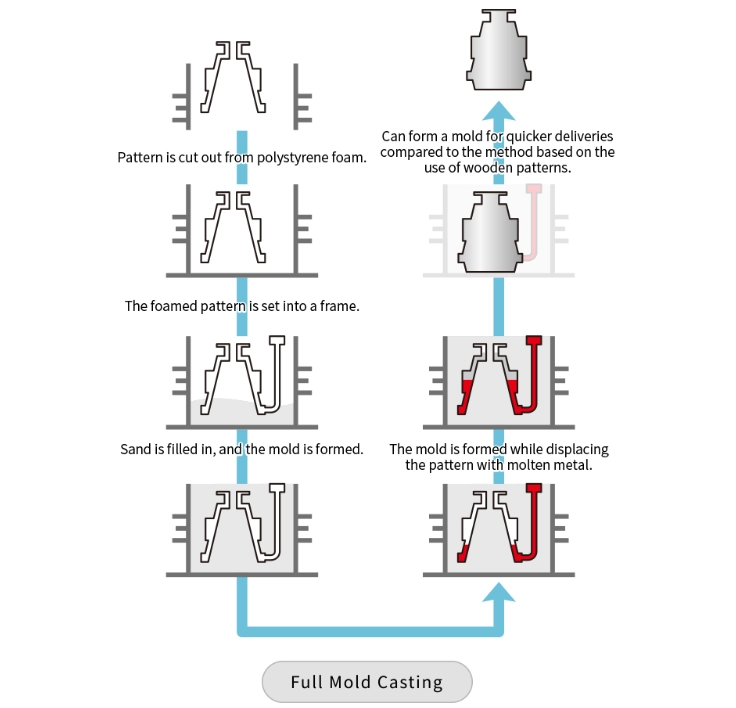

What Is Full-Mold Casting?

Full-mold casting is another evaporative-pattern casting type. It uses a wax mold but also relies on polystyrene foam as the base pattern. Like lost-foam, it uses a foam mold that vaporizes when heated.

The key twist is bonded sand. The foam pattern gets surrounded by sand. When molten metal pours in, it zaps the foam and takes its shape in the sand setup. The casting cools, usually at room temp, and then gets pulled out.

Advantages of Lost-Foam Casting

Lost-foam casting is awesome for precision. It makes super accurate castings with no draft or parting lines. This is great for tricky shapes where exact sizes matter.

Plus, it’s a simpler process. It needs fewer steps than many casting methods, including full-mold. This can speed up work and cut labor costs.

Also, lost-foam patterns are light and easy to move. They allow near-net-shape production, so less machining or grinding is needed after.

Advantages of Full-Mold Casting

Full-mold casting has its own cool perks. It’s a cheap and nifty way to make castings. The low cost comes from using affordable foam and reusable sand molds.

It also nails detailed shapes. The sand around the mold keeps things sturdy during pouring and cooling, cutting down on flaws like warping or shrinking.

This makes full-mold great for medium-to-large castings where a nice surface and exact sizes matter, but keeping costs low is key.

Hangzhou Ouchen: A Leading Manufacturer of Lost Foam Equipment in China

Hangzhou Ouchen Technology Co. , Ltd., based in Xindeng Town, Fuyang District, Hangzhou City, Zhejiang Province, is a top player in making smart lost-foam equipment. It’s a pro at high-end intelligent disappearing mode white area equipment.

The company mixes fancy German EPS/EPP tech with its own patented ideas for local foundry needs. Its lineup includes automated hydraulic forming machines for lost-foam molds (OC-CX-Y series), smart bead ripening systems for perfect expansion, and air energy heat pump drying units built for energy saving and eco-friendly vibes. These dryers use air energy heat pumps with high thermal efficiency as the main heat source.

Ouchen’s focus on quality and new ideas earned it the title of “Zhejiang Province Science and Technology Small-and-Medium-Sized Enterprise.” Its ongoing R&D makes it a key partner in China’s lost-foam industry groups. .

FAQ

Which process—lost-foam or full-mold—is better for complex shapes?

Both handle tricky shapes well. But lost-foam casting is a favorite for its spot-on, precise castings with no draft or parting lines.

Is there a cost difference between lost-foam vs full-mold casting?

Yup. Full-mold casting is a cheap and effective way to create castings.

Are both methods environmentally friendly?

Lost-foam has a slight edge with less waste and fewer steps. Its heat pump dryer sticks to energy-saving and eco-friendly designs, ensuring zero emissions during drying.

Does Hangzhou Ouchen offer custom equipment solutions?

Yes. EPS, EPP, ETPU, EPC white area equipment makers design full solutions with pro skills and quality to bring value to clients.

How does automation improve these processes?

Automation cuts human mistakes and boosts steady results. Ouchen’s forming machines have smart auto controls, using detection, sensing, and tweaks for full automation.

By understanding the differences between lost-foam and full-mold casting—and teaming up with suppliers like Hangzhou Ouchen—makers can choose wisely for their production goals.