Since its creation in the early 1950s, đúc bọt bị mất has grown into a favored method for making very detailed and exactly sized metal items in many fields. It cuts down on extra cutting work and lowers making costs. This casting way gives a cheap and quick fix for foundries. This piece looks into the basic ideas of lost-foam casting, its good points, common uses, and the clear steps in the process.

Những gì bị mất bọt đúc?

Đúc bọt bị mất is a kind of metal casting method that uses polystyrene foam patterns or molds to make metal parts with great detail and accuracy. In this way, a foam pattern (usually made of expanded polystyrene, EPS) is shaped like the wanted final part. This foam pattern then gets covered with a refractory (insulation) paint. It is put inside loose dry sand. Then, molten metal is poured right onto it. The hot metal turns the foam mold into gas (or “burns it away”). At the same time, it fills the empty space left behind. This forms the metal casting. Since the foam vanishes during pouring, the process is sometimes called “lost-mold casting.”

This method works especially well for making small to medium-sized metal parts with tricky shapes. It gives fine surface finishes and close size limits. It also skips the need for fancy cores or after-casting work.

Ưu điểm của việc đúc bọt bị mất

Lost-foam casting brings several strong benefits when compared with older casting ways:

High detail and dimensional accuracy — The foam pattern can copy hard shapes, even with thin walls, inside paths, or fancy designs. So, the metal parts show those details exactly.

Reduced machining and finishing requirements — The process often makes near-net-shape castings with smooth surfaces. This cuts or removes the need for extra cutting, grinding, or surface work.

Lower labor and production costs — Fewer steps and easier tools than traditional sand casting or investment casting drop the work and extra costs in foundries.

Greater design freedom — Without limits from cores or molds in usual casting, designers can build more tricky shapes with inside features, undercuts, and detailed parts.

Material versatility — Many metals like cast iron, ductile iron, alloy steels, carbon steel, aluminum alloys, and ferrous alloys can be cast with this method.

As a result, lost-foam casting is often cheaper and faster than some other casting ways, especially when high accuracy and hard shapes are needed.

When to Use Lost Foam Casting

Lost-foam casting shines when making parts or products that:

Need complex geometries — such as thin walls, internal channels, undercuts, or detailed outer shapes.

Require high dimensional accuracy and tight tolerances.

Benefit from smooth surface finish and minimal post-processing.

Are made in small to medium batches or where changing tools for traditional molds would cost a lot.

Use materials like cast iron, ductile iron, alloy steel, carbon steel, or aluminum alloy — fit for the lost-foam setting.

Industries and common uses include automotive (e.g., engine blocks, cylinder heads, gearbox housings), agriculture, machinery, defense, plus tricky castings for pumps, valves, housings, housings for burners or fixtures, and even detailed art or building metalwork.

When the design needs tricky inside paths, thin walls, or detailed outer features — and when cutting machining and finishing costs matters most — lost-foam casting turns into a very good choice.

Lost Foam Casting Process Steps

Below is a clear breakdown of the usual steps in a lost-foam casting process:

Making the Design Pattern

First, a pattern of the wanted final metal part is planned — often with computer-aided design (CAD) — and turned into an expanded polystyrene (EPS) foam mold. Foam patterns may be cut from a solid foam block or made by molding/injection ways (for big production). For very hard designs, several foam pieces may be glued together to shape the pattern.

2. Applying Insulation Paint to the Foam Mold

Once the foam pattern is done, it gets covered with a refractory or insulation paint. This layer guards the foam during the metal pour. It also makes sure the hot metal flows well into the space left by the foam. It keeps the mold strong. The painted mold is then dried in air.

3. Inserting the Mold into a Sand Flask and Sand Packing

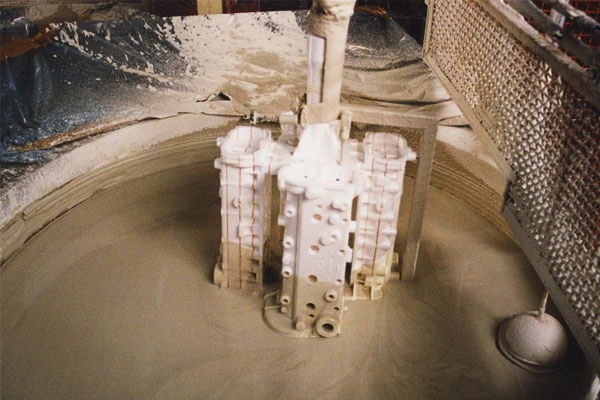

After drying, the painted foam pattern is set into a flask (a box for casting). It is surrounded by unbonded dry sand. The sand is pressed around the mold to hold and steady it. A sprue (for metal pouring) and vent paths (for gas escape) are also added as part of the flask setup.

4. Pouring the Molten Metal

Molten metal is poured through the sprue. As the metal touches the foam mold, the foam turns to gas (or “burns out”). The metal flows into the space made by the foam. The sand holds the metal flow and final hardening.

5. Retrieving the Final Product

Once the metal hardens and cools enough, the sand is taken away. The casting is pulled out. Because the casting fills the spot left by the foam mold, the final metal part matches the shape and detail of the first foam pattern closely. It often needs little or no after-cutting.

Why Lost Foam Casting Is Increasingly Preferred for Ductile Iron and Complex Castings

Lost-foam casting draws special interest for ductile iron and complex-metal castings. It can make near-net-shape parts with fewer cores and little machining. Foundries making ductile iron items — such as inside paths, thin-walled housings or hard shapes — gain from the steady hardening action and high surface quality possible with lost-foam casting.

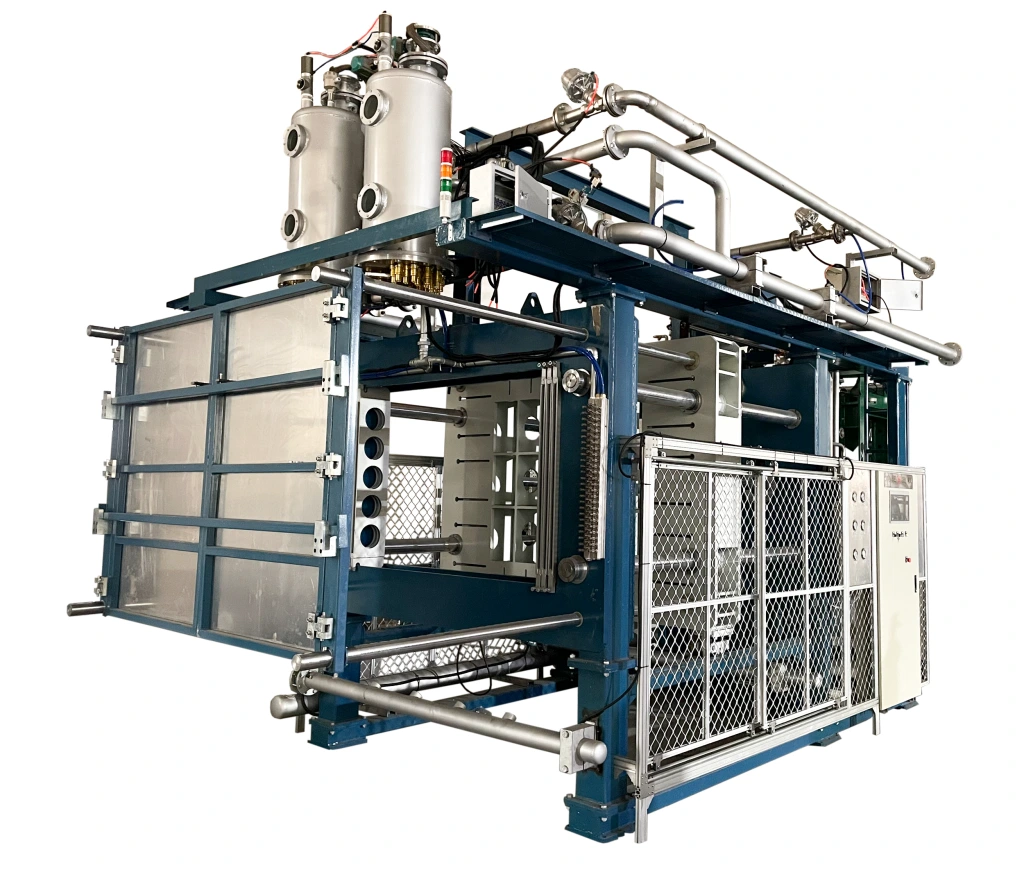

Moreover, when joined with a full lost-foam casting line (including EPS-molding machines, pre-foaming, bead handling, drying, vacuum systems, and coating equipment), foundries can reach high speed, automation, and less waste. This makes lost-foam casting a strong pick over older methods.

Summary

Lost-foam casting is a strong and flexible casting method. It fits best for making complex, detail-filled, and exactly sized metal parts with little after-work. The process focuses on building a foam pattern that is coated, placed in dry sand, and then swapped by molten metal that turns the foam to gas. This yields a metal casting that copies the foam’s shape perfectly.

Thanks to the method’s built-in good points — design flexibility, accuracy, less machining, work and cost savings — lost-foam casting is used widely across fields from automotive to agriculture, machinery, and more.

For foundries wanting to make complex ductile iron or aluminum parts quickly and cheaply, lost-foam casting stands as a great pick.

Câu hỏi thường gặp

Q: What types of metals can be used in lost-foam casting?

A: Lost-foam casting supports a wide range of metals, including cast iron, ductile iron, alloy steels, carbon steel, ferrous alloys, and aluminum alloys.

Q: Are post-casting machining and finishing always required?

A: Not necessarily — because lost-foam casting can produce near-net-shape parts with fine detail and smooth surface finish, many castings require little to no additional machining or finishing.

Q: Is lost-foam casting suitable for large metal parts?

A: It depends on the size and complexity. The process is most efficient for small to medium-sized complex parts. For very large castings, traditional casting methods or specialized equipment might be more appropriate.

Q: How does lost-foam casting compare to traditional sand casting or investment casting in cost and time?

A: Lost-foam casting generally reduces production complexity, tooling costs, and machining/post-processing time, often resulting in lower overall fabrication costs and shorter lead times compared to traditional sand casting or investment casting for complex shapes.

Advance Your Foundry With a Trusted Lost-Foam Casting Supplier

If a foundry seeks an end-to-end, intelligent, and energy-efficient lost-foam casting solution, Công nghệ OC presents an ideal partner. As a recognized high-tech enterprise based in Hangzhou, OC Technology specializes in producing high-end, automated “white-area” equipment for lost-foam casting — including foam molding machines, pre-foaming equipment, air dryers, and full casting lines.

OC Technology serves foundry-grade clients worldwide and offers turnkey casting line supply, advanced automation, and after-sales services designed for partners.

Manufacturers or suppliers interested in elevating their casting operations with precision, efficiency, and automation are encouraged to liên hệ với công nghệ OC to explore tailored lost-foam casting line solutions.