The machine adjusts the plate size from length and width according to the customer’s requirements. The encoder control rod is used to adjust the length and width of the plate steplessly. The customer only needs to input the adjustment number on the touch screen, and the equipment will automatically adjust the size. It is easy to operate. The advanced material and post adjustment process can be selected to greatly improve the mixing ratio of recycled materials.

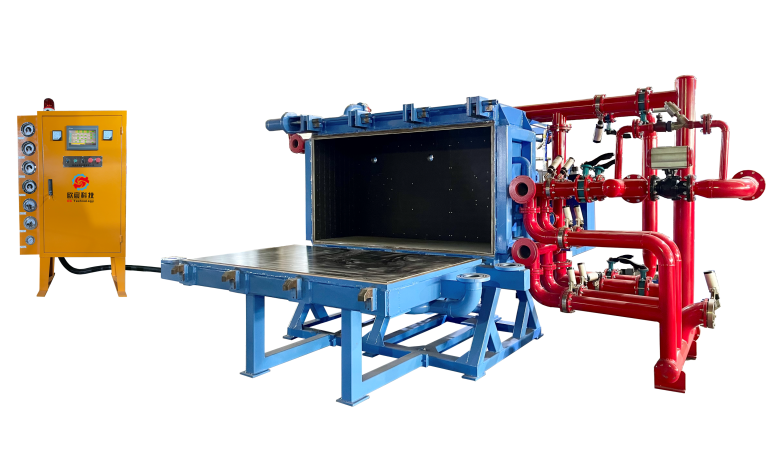

♦ Control system

Adopting PLC programmable controller and touch screen control, fully automated operating system, low failure rate, easy maintenance.

An optional expert control system can be selected to achieve adaptive proportional servo adjustment of steam volume and heating temperature, and a communication interface is set up to remotely control equipment operation and product quality.

♦ Process characteristics

Adopting the sequence of negative pressure and pulse high flow cold air for cooling, the efficiency is doubled.

Fully automatic pneumatic feeding, vacuum assisted feeding, ensuring consistency in board density.

One time molding, optional conveyor belt for unmanned and automatic cyclic production.

The exclusive design of the anti 7-shaped and all-round dispersion sequence steam drainage penetration heating method solves the problem of uniform heating temperature for large-sized disappearing template materials, and improves the adhesion and curing uniformity of the product.

♦ Production efficiency

Co polymer and EPS can be used.

Fast feeding speed and cooling speed.

High production efficiency, the production cycle of each foam board is 8-10 minutes.

The produced foam plate has low water content, high quality and no deformation.

Low energy consumption and low cost in the production process.

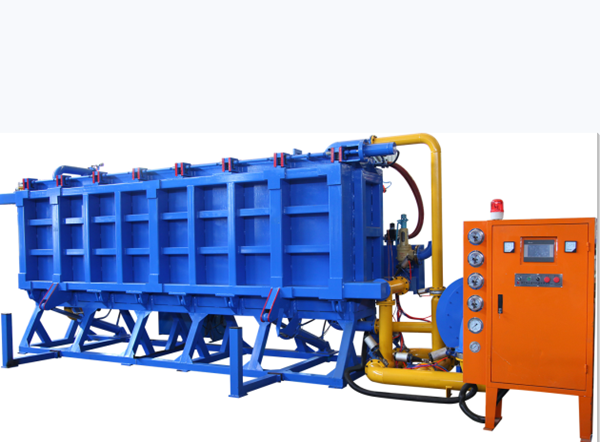

♦ Structural Design

The body is made of thickened square steel and high-strength steel plate welded together, with high strength, not easy to deform, and sturdy and durable.

Centralized control of hydraulic station, hydraulic single door opening, hydraulic ejection demolding and automatic locking mechanism, without any safety hazards.

The control instruments, electrical and pneumatic components, various valves and other supporting parts used are all high-quality branded products at home and abroad, and the performance of the machinery and equipment is stable and reliable.